Description

JR-160CNC Auto Pipe Cutter: High-Efficiency Cutting for Industrial Pipes

In industrial pipe processing—from construction scaffolding tubes to electrical conduit pipes—two critical bottlenecks slow production: low multi-pipe capacity (traditional cutters handle 1 pipe per cycle) and inconsistent precision (manual feeding causes ±0.2mm length errors). The JR-160CNC Auto Pipe Cutter (a fully automated CNC pipe-cutting machine) resolves these issues: it integrates multi-pipe cutting capability, high-performance motor/saw blade, and intuitive parameter control to cut 1+ pipes per cycle, deliver ±0.1mm accuracy, and boost production efficiency by 3x.

1. What Is the JR-160CNC Auto Pipe Cutter?

The JR-160CNC Auto Pipe Cutter is a dedicated industrial machine designed for high-volume cutting of hollow pipes (outer diameter: 60–100mm, wall thickness: 1.0–5.0mm). Unlike single-pipe cutters, it is optimized for small-batch to large-scale production: its multi-pipe cutting design allows 1+ pipes to be processed per cycle, while the 1.5KW high-performance motor and specialized saw blade ensure fast, clean cuts (150+ pipes per hour).

Its core advantage lies in versatility + efficiency: it cuts multiple pipe types (steel, aluminum, copper, PVC) and adapts to both small-batch custom orders and large-scale mass production. For construction material manufacturers, this automated pipe cutter reduces pipe-cutting labor costs by 60% (from 2 operators to 1 part-time staff).

2. Core Features of This CNC Pipe Machine

This CNC pipe machine stands out for 3 industry-tailored features:

2.1 Multi-Pipe Cutting for Flexible Production

The machine’s defining feature is multi-pipe cutting capability: it can process 1 or more pipes per cycle, making it suitable for both small-batch custom orders (e.g., 50 PVC conduit pipes) and large-scale mass production (e.g., 1,000 steel scaffolding tubes per day). This flexibility eliminates the need for separate machines for different order volumes.

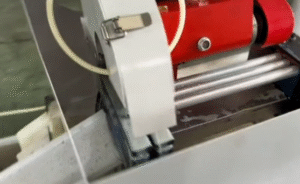

2.2 High-Efficiency Motor & Saw Blade

Equipped with a 1.5KW high-performance main motor and specialized saw blade, the machine delivers:

- Fast Cutting Speed: 150+ pipes per hour (3x faster than single-pipe semi-automatic cutters);

- Clean Cuts: Minimal burrs (surface roughness ≤Ra1.6) even in 5mm-thick steel pipes;

- Long Blade Life: 2,000+ cuts per blade (vs. 1,200 cuts for generic blades).

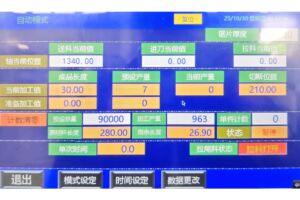

2.3 Intuitive Display Screen & Parameter Control

The machine is fitted with a digital display screen that simplifies operation:

- Intuitive Interface: Visualizes cutting parameters (length, quantity, speed) in real time;

- Convenient Adjustment: Modifies cutting parameters in 0.1mm increments without manual calibration;

- Error Alerts: Notifies operators of issues (e.g., low air pressure) to prevent defects.

A Guangdong-based construction material manufacturer reported that after adopting this high-efficiency cutter, parameter setup time per batch dropped from 8 minutes to 1 minute.

3. Technical Specifications of the JR-160CNC Auto Pipe Cutter

Every parameter of the JR-160CNC Auto Pipe Cutter is calibrated for industrial pipe processing:

4. Application Scenarios of This Auto Pipe Cutter

This auto pipe cutter excels in 3 key industrial pipe workflows:

4.1 Construction Scaffolding Tubes

Steel scaffolding tubes (outer diameter 60mm, wall thickness 3mm) require high-volume, consistent cuts. The machine’s multi-pipe cutting capability processes 2 tubes per cycle, delivering 200+ tubes per 8-hour shift—meeting construction project deadlines.

4.2 Electrical Conduit Pipes

PVC electrical conduit pipes (outer diameter 80mm) demand burr-free cuts to avoid damaging wiring. The machine’s specialized saw blade produces clean cuts, eliminating post-processing deburring and reducing labor costs by 15%.

4.3 Industrial Equipment Pipes

Aluminum equipment pipes (wall thickness 5mm) require high precision to fit into machinery assemblies. This CNC pipe cutter’s ±0.1mm accuracy ensures these pipes meet equipment manufacturing standards (ISO 9001).

5. Operation & Maintenance of the JR-160CNC Auto Pipe Cutter

The JR-160CNC Auto Pipe Cutter is designed for 1-hour operator training and 98% uptime:

5.1 Basic Operation Workflow

- Load the pipe parameter library (pre-programmed for scaffolding/conduit pipes) via the display screen;

- Input the desired pipe length (e.g., 2000mm) and quantity (e.g., 400);

- Load 1+ pipes into the auto-feeding tray (max 10 pipes per load);

- Press “Start” to initiate fully automated cutting (feeding, clamping, cutting, discharging).

Auto Frame Aluminum Components (Jiurun US Client Case)

5.2 Scheduled Maintenance

- Daily: Clean pipe chip collection tray and check air pressure (4–6kg/cm²);

- Weekly: Lubricate feeding rails with lithium-based grease (NLGI Grade 2);

- Monthly: Calibrate cutting length with a precision tape measure (included);

- Quarterly: Replace saw blades if cut roughness exceeds Ra1.6.

Jiurun Technology provides a 1-year full warranty and 24/7 remote technical support for this automated pipe machine, minimizing downtime for pipe production lines.

6. Why Choose the JR-160CNC Auto Pipe Cutter?

For industrial pipe processors, the JR-160CNC Auto Pipe Cutter delivers 3 strategic benefits:

- Flexible Production: Multi-pipe cutting adapts to small-batch and large-scale orders;

- Cost Savings: 3x faster efficiency reduces labor costs by 60%;

- Consistent Quality: ±0.1mm accuracy meets industrial pipe assembly standards.

Ethan Campbell –

“As the first user of the JR-160CNC in New Zealand, this fully automatic pipe cutter has transformed our workflow! Previously, cutting different-diameter aluminum pipes required 10+ minutes of manual setup (and 8% material waste from mis-cuts)—now this machine switches between 20mm-160mm pipes in 30 seconds, with 0.05mm-level length precision. The fully automatic feeding & cutting runs 8 hours straight without supervision, doubling our daily pipe processing output. It’s the most reliable, efficient pipe-cutting solution we’ve ever used!”