Description

JR-455CNC Auto Aluminum Cutter: Full CNC Cutting for Thin-Wall Profiles

In thin-wall aluminum processing—for automotive brackets, furniture frames, and electrical enclosures—two critical challenges often hinder production: deformation during clamping (manual clamps warp 1–3mm thin profiles) and inconsistent burrs (semi-automatic feed causes uneven cuts). The JR-455CNC Auto Aluminum Cutter (a full CNC upper-lower feed machine) resolves these issues: it integrates servo automatic feeding, anti-injury clamping, and 2500rpm spindle speed to deliver deformation-free, burr-free cuts with ±0.1mm accuracy—all with minimal operator intervention.

1. What Is the JR-455CNC Auto Aluminum Cutter?

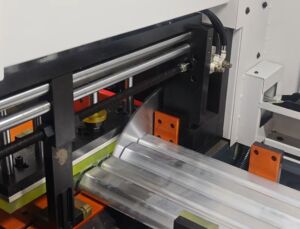

The JR-455CNC Auto Aluminum Cutter is a fully automated CNC machine designed for high-volume cutting of thin-wall aluminum profiles (up to 125mm height, 270mm width). Unlike semi-automatic alternatives, it uses upper-lower feed technology: the saw blade moves vertically (upper-lower) while the profile is secured by anti-deformation clamps, ensuring even pressure distribution across thin walls.

Its core advantage lies in precision for thin materials: the anti-injury clamping device (paired with pneumatic pressure control) secures profiles without warping, while the 5.5KW main motor delivers consistent torque for clean cuts—even in 1mm-thick aluminum. For furniture manufacturers, this CNC upper-lower feed cutter cuts 250+ thin profiles per hour, with no need for post-processing sanding.

2. Core Features of This Automated Thin-Profile Cutter

This automated thin-profile cutter stands out for 3 tailored features for thin-wall aluminum processing:

2.1 Servo Automatic Feeding & Clamping

Equipped with servo-driven feeding (700mm maximum stroke) and automatic clamping devices, the machine eliminates manual intervention:

- Auto Feeding: Reciprocating stroke adjusts to profile length (up to 700mm), with ±0.05mm positioning accuracy;

- Auto Clamping: Pneumatic clamps (adjustable pressure: 4–8kg/cm²) secure thin profiles without deformation—critical for 1–3mm wall thicknesses.

This automation cuts setup time by 80% (from 10 minutes per batch to 2 minutes) for typical users.

2.2 Anti-Deformation Clamping & Burr-Free Cuts

The machine’s anti-injury material device is engineered for thin-wall profiles: thin-walled clamps distribute pressure evenly, preventing warping while holding the profile tightly. Paired with a Φ355–455mm aluminum-specific saw blade (2500rpm spindle speed), this combination produces a cut surface roughness of ≤Ra1.6—completely burr-free, even in 1mm aluminum.

A Zhejiang-based furniture manufacturer reported that after adopting this CNC aluminum cutting system, their thin-profile reject rate dropped from 12% to 0.5%.

3. Technical Specifications of the JR-455CNC Auto Aluminum Cutter

Every parameter of the JR-455CNC Auto Aluminum Cutter is calibrated for thin-wall aluminum processing:

4. Application Scenarios of This Upper-Lower Feed Machine

This upper-lower feed machine excels in 3 key thin-wall aluminum workflows:

4.1 Automotive Brackets

Automotive thin-wall aluminum brackets (1–2mm thickness) require deformation-free cuts to maintain structural integrity. The machine’s anti-deformation clamping ensures these brackets meet automotive safety standards (ISO 16750).

4.2 Furniture Frames

Lightweight furniture frames (e.g., office desk legs) use 1–3mm thin aluminum. The machine’s burr-free cuts eliminate post-processing, reducing labor costs for furniture manufacturers by 15%.

4.3 Electrical Enclosures

Electrical enclosure panels (thin aluminum sheets) demand clean, flat cuts to ensure seal integrity. This CNC cutter’s ±0.1mm accuracy ensures panels fit seamlessly, meeting IP65 waterproof standards.

5. Operation & Maintenance of the JR-455CNC Auto Aluminum Cutter

The JR-455CNC Auto Aluminum Cutter is designed for 1-hour operator training and 98% uptime:

5.1 Basic Operation Workflow

- Load the profile parameter library (pre-programmed for automotive/furniture parts) via the 7-inch touchscreen;

- Input the desired cut length (e.g., 600mm) and quantity (e.g., 300);

- Load profiles into the auto-feeding tray (max 15 profiles per load);

- Press “Start” to initiate fully automated cutting (feeding, clamping, and cutting).

Jiurun’s CNC system enables intelligent control for aluminum cutting precision and efficiency

5.2 Scheduled Maintenance

- Daily: Clean chip collection tray and check air pressure (4–8kg/cm²);

- Weekly: Lubricate feeding rails with industrial-grade grease;

- Monthly: Calibrate cutting accuracy with a precision dial gauge (included);

- Quarterly: Replace saw blades if cut roughness exceeds Ra1.6.

Jiurun Technology provides a 1-year full warranty and 24/7 remote technical support for this automated aluminum cutter, minimizing downtime for thin-profile production lines.

6. Why Choose the JR-455CNC Auto Aluminum Cutter?

For thin-wall aluminum processors, the JR-455CNC Auto Aluminum Cutter delivers 3 strategic benefits:

- Deformation-Free Cuts: Anti-injury clamping preserves thin-profile integrity;

- Cost Savings: Burr-free cuts eliminate post-processing labor;

- Efficiency: 250+ profiles per hour to meet large-batch order deadlines.

Pierre Dubois –

“As the first French user of the JR-455CNC with top-bottom auto feeding, it’s solved our biggest labor pain point! Previously, 2 workers spent 4 hours daily manually loading/unloading aluminum profiles (with frequent positioning errors)—now this machine handles full auto feeding/cutting/unloading, needing only 1 worker to supervise 2 machines at once. The dual feeding system cuts 2 profiles simultaneously, boosting our daily output by 150%, and the 0.03mm positioning precision eliminates 99% of rework. It’s the ultimate efficiency upgrade for our mass aluminum production line!”