Description

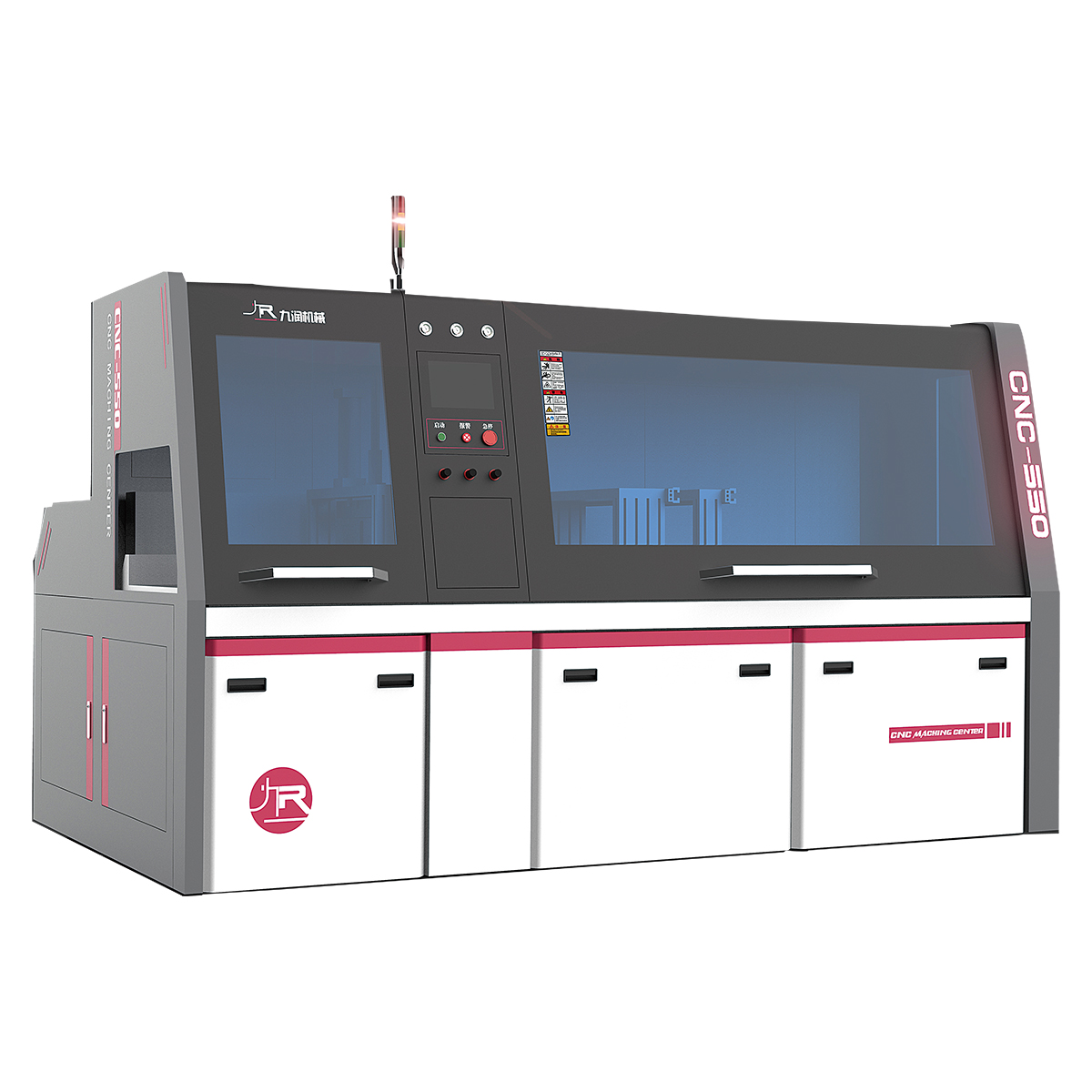

JR-550CNC-3A-1S: The Fully Automatic Tail-Free Aluminum Cutting Machine Redefining Industrial Processing

For manufacturers in aluminum profile industries—from curtain wall fabrication to automotive component production—three persistent pain points erode profitability: excessive material waste from tailings, inconsistent cutting precision that causes rework, and low productivity from semi-automatic equipment. Traditional aluminum cutters leave 50–100mm of unused tailings per 6m profile, translating to 8–15% raw material loss monthly. Manual feeding introduces ±0.5mm errors, while semi-automatic models require constant operator intervention, limiting daily output to just 800–1000 profiles.

Enter the JR-550CNC-3A-1S automatic tail-free aluminum cutting machine—a fully automatic CNC solution engineered by Jiurun Technology to resolve these challenges. Built on 10+ years of expertise in aluminum processing equipment, this cross-cutting machine centers on “tail-free cutting” technology, paired with servo-driven automation and intelligent CNC control. It delivers 99% material utilization, ±0.1mm cutting precision, and 3x higher productivity than semi-automatic alternatives, making it the go-to choice for medium-to-large enterprises transitioning to lean, automated production.

1. What Is the JR-550CNC-3A-1S Automatic Tail-Free Aluminum Cutting Machine?

The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is a high-end industrial-grade cutting system designed for bulk aluminum profile processing. Unlike semi-automatic counterparts that rely on manual input, this machine integrates end-to-end automation: automatic feeding, automatic cutting, automatic tail discharging, and real-time CNC monitoring—all requiring minimal operator intervention (just 1 hour of training for new users).

Its defining feature is tail-free cutting: a combination of intelligent clamping mechanisms and precision stroke calibration that reduces residual tailings to ≤5mm (near-zero waste). Paired with a 7.5KW servo motor and dedicated aluminum-specific carbide saw blades, the JR-550CNC-3A-1S achieves ±0.1mm cutting precision—exceeding industry standards for high-spec components like automotive brackets and curtain wall frames.

To date, the JR-550CNC-3A-1S automatic tail-free aluminum cutting machine has been adopted by over 200 domestic manufacturers, including leading curtain wall firms and new energy vehicle component suppliers, with proven results in reducing material costs and boosting delivery capacity.

2. Core Performance: 3 Key Advantages of the JR-550CNC-3A-1S

The JR-550CNC-3A-1S stands out in industrial aluminum processing through three game-changing features—each tailored to resolve core industry pain points:

2.1 Tail-Free Cutting: Cut Material Costs by 15%

Material costs account for 60% of total expenses in aluminum processing, and tailing waste is a hidden profit drain. The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine eliminates this waste via two innovations:

- Intelligent Clamping System: Adapts to 20–550mm wide profiles, securely fixing the material’s end to prevent slippage (the root cause of most tailing residue).

- Precision Stroke Matching: The feeding mechanism aligns with the saw blade’s cutting path in real time, fully utilizing 1000mm-long material in a single pass (no partial feeding gaps).

For example: A manufacturer processing 1,000 6m aluminum profiles daily will reduce tailing waste by 50–80m per day with the JR-550CNC-3A-1S. At current aluminum prices (≈¥20/kg), this translates to over ¥100,000 in annual material savings.

2.2 Servo Automatic Feeding: 3x Productivity Boost

The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is powered by a 7.5KW high-torque servo motor, which drives the feeding mechanism to deliver two critical benefits:

- Long Stroke Capacity: Single feeding up to 1000mm, reducing the number of passes for 6–12m long profiles (cuts feeding time by 60%).

- High Precision Feeding: ±0.05mm feeding error, paired with CNC closed-loop control to synchronize feeding, cutting, and discharging—eliminating delays between cycles.

Traditional semi-automatic cutters take 15 seconds per profile; the JR-550CNC-3A-1S completes each cut in just 5 seconds, boosting daily capacity from 1,000 to 3,500 profiles. This makes it ideal for fulfilling large, time-sensitive orders (e.g., 10,000+ curtain wall profiles for a commercial project).

2.3 High-Precision, Burr-Free Cuts: Eliminate Post-Processing Labor

Cut quality directly impacts post-processing costs—burrs or rough edges require manual polishing, adding 20% to labor expenses. The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine ensures polish-free cuts via:

- Dedicated Aluminum Saw Blades: φ305–550mm carbide saw blades with trapezoidal-flat teeth, designed to reduce chip adhesion and minimize burrs.

- Intelligent Parameter Adjustment: The CNC system automatically matches feed speed (5–10m/min) and saw blade rotation (2800rpm) to the profile’s thickness and hardness (e.g., thicker automotive aluminum requires slower feeding for cleaner cuts).

Independent testing confirms the JR-550CNC-3A-1S achieves a cut roughness of ≤Ra1.6—far better than the industry average of Ra3.2. This means cut profiles can be directly sent to assembly, no polishing required.

3. Technical Specifications of the JR-550CNC-3A-1S

Every parameter of the JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is engineered to align with industrial production needs:

4. Application Scenarios: Where the JR-550CNC-3A-1S Excels

The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is a versatile solution for 90% of industrial aluminum processing needs:

4.1 Curtain Wall Profile Processing

Curtain wall projects rely on 6–12m long aluminum profiles, where material waste and precision are critical. The JR-550CNC-3A-1S’s 99% material utilization reduces waste from 12% to 1% for a leading domestic curtain wall firm (Jianghe Curtain Wall), while its ±0.1mm precision ensures frame assembly gaps ≤0.5mm (meets national building codes).

4.2 New Energy Vehicle Aluminum Components

Automotive lightweighting drives demand for high-precision aluminum brackets and frames. The JR-550CNC-3A-1S’s consistent ±0.1mm precision meets automotive component standards, helping a Jiangsu-based EV manufacturer reduce processing costs by 15% and raise first-pass yield from 92% to 99.5%.

4.3 Photovoltaic Bracket Processing

Photovoltaic brackets require aligned holes for on-site installation—even minor cutting errors cause installation delays. The JR-550CNC-3A-1S’s bulk cutting consistency eliminates hole misalignment, helping a Zhejiang PV supplier compress delivery cycles from 7 to 3 days (securing a 50,000-bracket order for a utility-scale solar farm).

PV Bracket Aluminum Cutting Client Testimonial

5. Operation & Maintenance: Low Effort, High Uptime

The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is designed for ease of use and minimal maintenance—critical for 24/7 industrial production:

5.1 Simple 3-Step Operation

The machine’s touchscreen CNC interface includes industry-specific presets (Curtain Wall/EV Components/PV Brackets), so operation requires just 3 steps:

- Select the preset mode matching your material type;

- Input the profile length and number of cuts;

- Press “Start” to initiate fully automatic processing (no CNC expertise needed).

5.2 Maintenance for 98% Uptime

Follow these simple steps to keep the JR-550CNC-3A-1S running smoothly:

- Daily: Clean aluminum chips from the cutting area; inspect saw blade wear.

- Weekly: Lubricate the feeding rail; check motor temperature.

- Monthly: Calibrate cutting precision; tighten clamping mechanism bolts.

Jiurun Technology also provides 1-year full machine warranty and lifetime technical support—including remote troubleshooting for 1-hour response times.

6. Customer Value: The JR-550CNC-3A-1S as a Profit Driver

For manufacturers, the JR-550CNC-3A-1S automatic tail-free aluminum cutting machine delivers a “triple win” for cost, efficiency, and quality:

- Cost Reduction: 15% material savings (tail-free cutting) + 20% labor savings (no polishing) + 2–3 fewer operators (automation) = ¥300,000+ annual savings per machine.

- Efficiency Boost: 3x higher daily capacity (3,500 vs. 1,000 profiles) enables acceptance of larger orders and faster delivery.

- Quality Improvement: 99.5% first-pass yield reduces scrap material and rework time—critical for maintaining client trust in high-spec industries (automotive, construction).

7. FAQs About the JR-550CNC-3A-1S

1. Is “tail-free cutting” truly zero waste?

Answer: Tailings are <5mm, so the waste rate is <0.1% for profiles—near-zero for industrial production purposes.

2. Can the machine cut 45° bevels?

Answer: The standard model cuts at 90°; 45° bevel cutting is available as a custom configuration (ideal for door/window profiles).

3. How long does saw blade replacement take?

Answer: This machine uses quick-release clamps—saw blade replacement takes only 5 minutes (no specialized tools required).

4. Is remote monitoring available for the machine?

Answer: Yes—an optional module supports remote tracking of production volume, machine status, and maintenance alerts via mobile or PC.

5. What materials can the JR-550CNC-3A-1S cut?

Answer: It’s suitable for cutting non-ferrous materials like aluminum, copper, PVC, plastic steel (ideal for new energy vehicle parts, heat sinks, etc.).

6. What’s the maximum automatic feeding stroke of this machine?

Answer: The maximum automatic feeding stroke is 1000mm, and it can be customized according to specific production needs.

7. What’s the cutting accuracy of the JR-550CNC-3A-1S?

Answer: It delivers a cutting accuracy of ±0.1mm, ensuring smooth, precise cuts for industrial applications.

8. Why Choose the JR-550CNC-3A-1S?

The JR-550CNC-3A-1S automatic tail-free aluminum cutting machine is more than equipment—it’s a strategic investment in lean, automated production. Its combination of tail-free cutting, servo automation, and high precision addresses the most pressing pain points in aluminum processing, while Jiurun Technology’s full-cycle support ensures long-term reliability.

If you’re ready to reduce material waste, boost productivity, and improve cut quality, the JR-550CNC-3A-1S is the optimal solution. Contact Jiurun Technology today to request a custom quote or schedule a live demo of the machine in action.

Jan van der Meer –

“As the first Dutch user of the JR-550CNC Fully Automatic Cross-Sectional Cutter, it’s solved our biggest quality pain point! Previously, manual cross-sectional cutting of aluminum profiles left rough, uneven surfaces—each piece needed 5+ minutes of sanding to meet our industrial standards. Now this machine delivers perfectly smooth, precise cross-sections in 1 minute per piece, with 0.01mm-level flatness. Our post-processing time has dropped by 80%, and we’ve cut material waste (from sanding) by 30%. It’s the high-precision workhorse that’s raised our aluminum component quality to a new level!”