Automated Production Line Integration Redefines Smart Manufacturing for Aluminum Processing

In the era of Industry 4.0, Jiurun aluminum cutting machine’s automated production line integration stands as a transformative force for manufacturers. It seamlessly syncs with upstream and downstream equipment, enabling lights-out production, real-time data tracking, and 40% efficiency gains—all while maintaining ±0.01mm precision. A Suzhou automotive parts giant shares, “Our Jiurun-integrated line runs 24/7 with 30% fewer operators, and product consistency hit 99.9%—a game-changer for our aluminum component supply chain.”

1. Smart Workflow Sync – From Raw Material to Finished Product

Jiurun’s automated integration isn’t just about standalone machines—it’s a holistic ecosystem. The cutting machine connects with feeders, conveyors, and quality inspection systems via industrial IoT, creating a closed-loop production flow. “We used to have bottlenecks between cutting and anodizing,” notes a Guangdong aluminum fabricator. “Jiurun’s integration eliminated 2 hours of daily downtime from manual handoffs.” The system auto-adjusts cutting parameters based on upstream material supply, ensuring zero waiting time.

2. Data-Driven Production – Real-Time Visibility & Control

At the core of this integration is a cloud-based dashboard that tracks OEE (Overall Equipment Efficiency), scrap rate, and energy consumption in real time. Managers can access data from any device, making decisions on the fly. A Shanghai aerospace supplier explains, “When our Jiurun line’s scrap rate spiked to 1.2%, the dashboard alerted us instantly—we fixed a blade wear issue in 15 minutes, avoiding thousands in losses.” This data layer also supports predictive maintenance, reducing unplanned downtime by 50%.

3. Scalable Modular Design – Grow With Your Business

Jiurun’s automated integration is modular, meaning factories can start small and expand. Add a second cutting station, a robotic loader, or a sorting module as demand rises—all without halting production. “We started with a single Jiurun machine and scaled to a 5-machine line in 18 months,” says a Zhejiang solar frame manufacturer. “The modular design made expansion seamless, and we never missed a delivery deadline.”

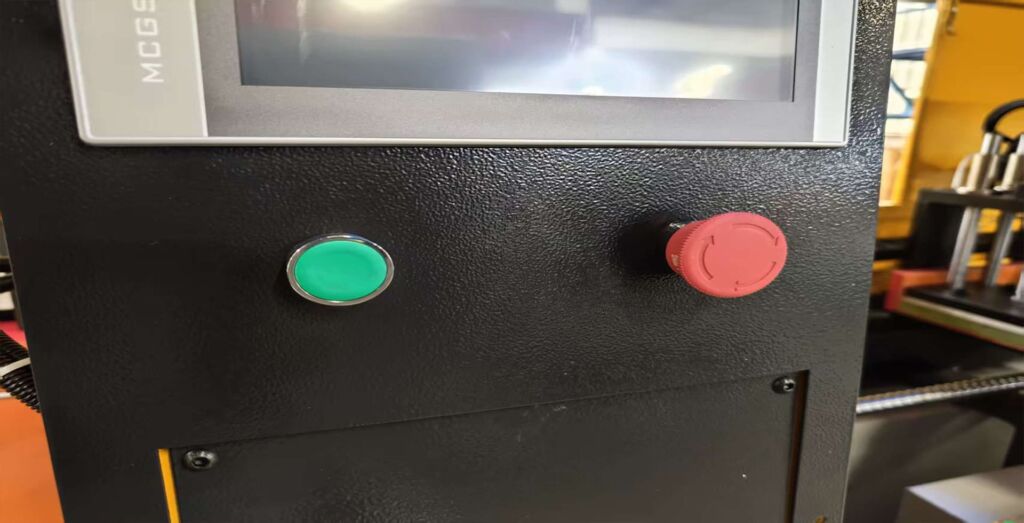

4. Compliance & Safety in Automated Environments

Even in fully automated setups, Jiurun prioritizes safety. The system includes interlocks, emergency stop protocols, and CE/ISO-certified components. “Our auditors were impressed by how Jiurun’s automation didn’t compromise safety,” shares a Jiangsu electronics enclosure producer. “The built-in safety checks mean we never have to choose between speed and compliance.”