Jiurun aluminum cutting machine client success stories span aerospace

automotive, and construction, delivering proven precision, efficiency, and reliability. A leading aerospace component supplier saw their aluminum scrap rate drop from 8% to 1.2% and production efficiency rise by 40% after adopting Jiurun aluminum cutting machines. This is the power of Jiurun’s tailored technology in action. For deeper insights into aluminum processing trends, explore [relevant industry report link].

1. Aerospace Industry – Precision at Scale

In aerospace, precision is non-negotiable. A major aircraft parts manufacturer uses a Jiurun aluminum cutting machine to process 7075-T6 aluminum for wing components, achieving ±0.01mm tolerance. “Before Jiurun aluminum cutting machines, inconsistent cuts were a constant issue,” shares their production manager. “Now, we meet aerospace standards effortlessly, and delivery times are 30% faster.” The Jiurun machine’s thermal stability ensures precision during 24/7 operations, a critical factor for aerospace’s tight deadlines. Dive into our [previous article on Jiurun’s R&D] to learn how technology powers this precision.

2.Automotive Sector – Efficiency & Consistency

Automotive manufacturers demand speed and consistency. A Shanghai car parts supplier switched to Jiurun aluminum cutting machines for aluminum door frame production.

The outcome? Daily output increased by 25%, with zero defects in six months. “The automatic tool-changing system in Jiurun aluminum cutting machines is a game-changer,” notes their engineer.

“Tool swaps used to take hours; now it’s done in seconds, and cuts are always perfect.” Jiurun’s intelligent error compensation adapts to material variations, ensuring every frame meets automotive-grade quality.

“Jiurun aluminum cutting machines have revolutionized our automotive production—efficiency, precision, and reliability all in one solution.”

Technical Director, Automotive Parts Supplier

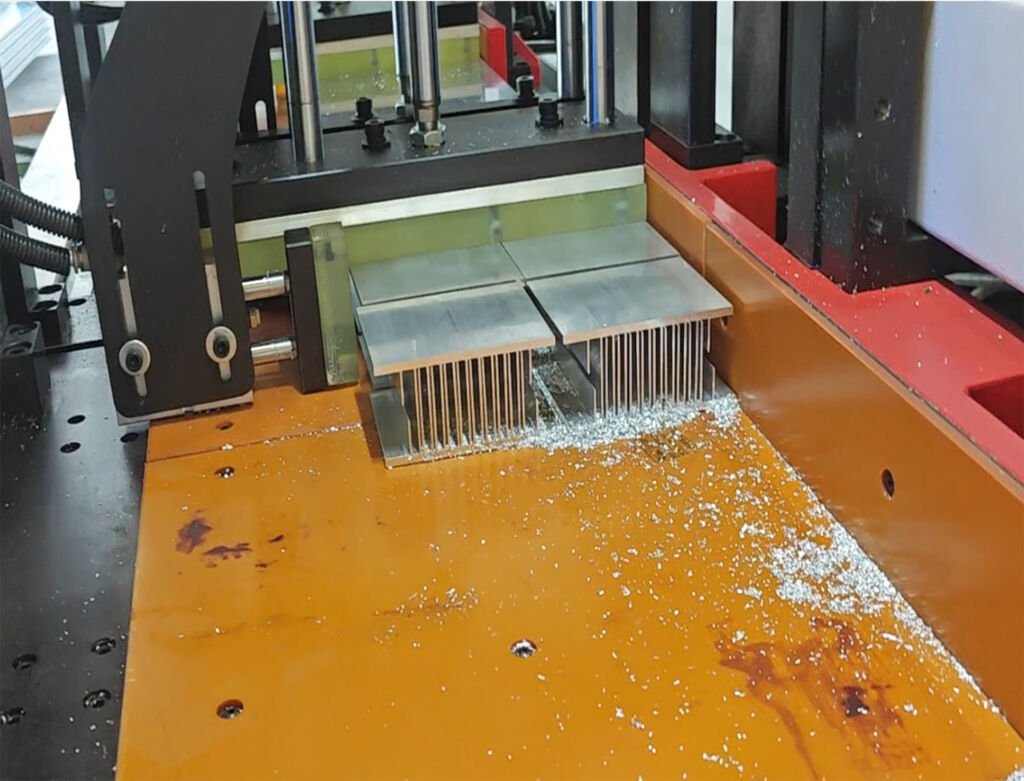

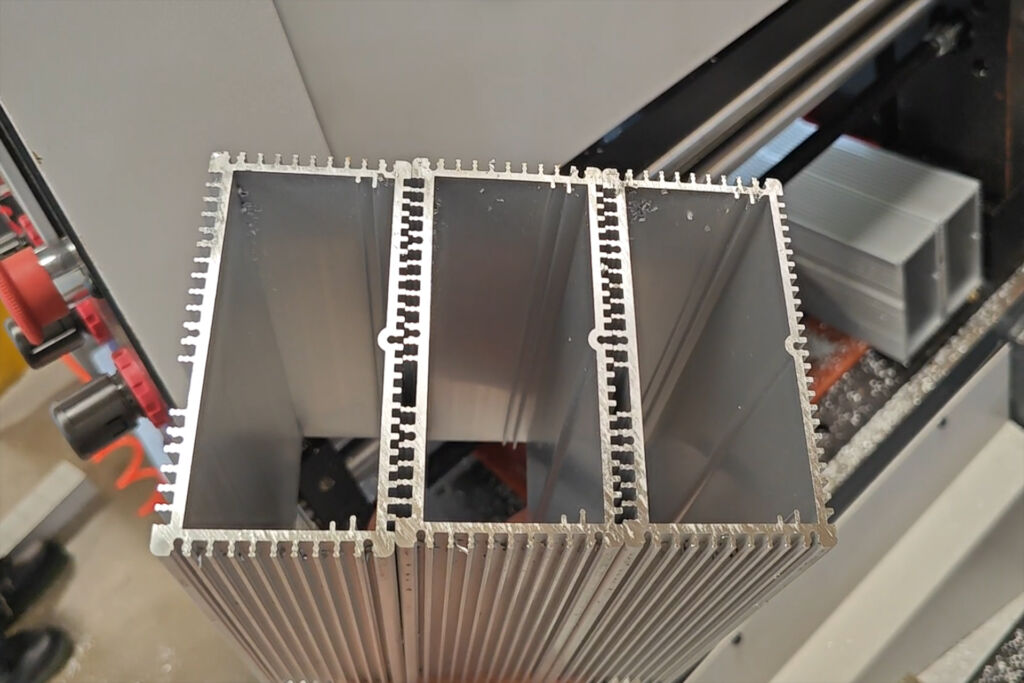

3. Construction Industry – Bulk Production & Durability

Construction requires high-volume aluminum extrusion, and Jiurun aluminum cutting machines deliver durability and speed. A Guangzhou construction material supplier operates three Jiurun aluminum cutting machines to produce standard and custom profiles. “These Jiurun machines have run non-stop for two years, and we’ve only replaced blades once,” says their operations director. The machines’ robust build and low maintenance needs align with construction’s demanding schedules. Additionally, Jiurun’s remote monitoring feature resolves 90% of issues offsite, saving time and costs.

4. Client Testimonials – Beyond the Numbers

Numbers tell part of the story; testimonials tell the rest. “Jiurun aluminum cutting machines are the backbone of our aluminum processing,” states a director at a leading electronics enclosure manufacturer. “Precision, reliability, and after-sales support—they exceed our expectations.” A custom aluminum fabricator adds: “We’ve tried other brands, but Jiurun aluminum cutting machines’ adaptability to our unique projects is unmatched.” These stories reflect Jiurun’s commitment to building long-term partnerships, not just selling machines.