Description

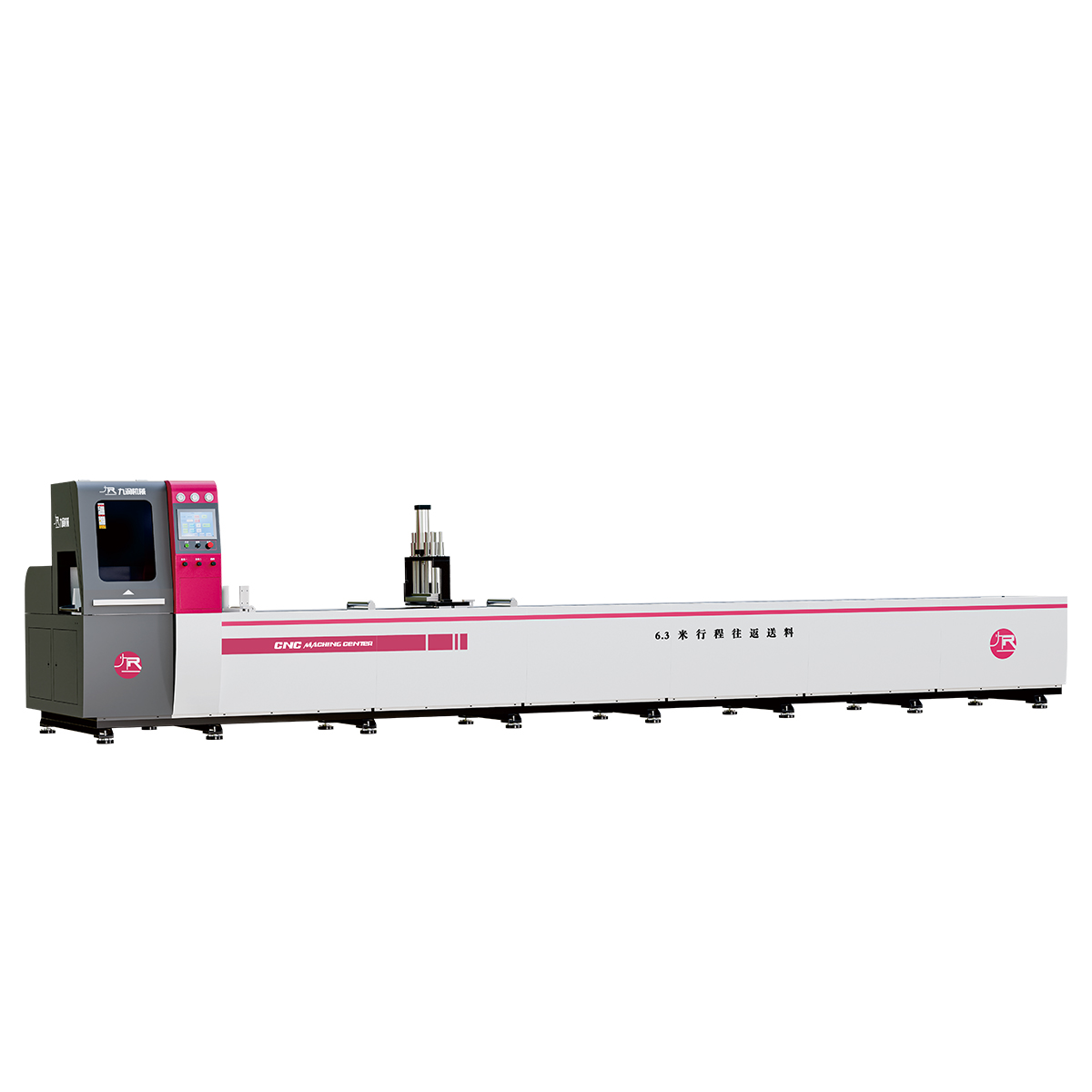

JR-650CNC Auto Aluminum Cutter: 6m Stroke Tail-Free Cutting for Large Profiles

In large-scale aluminum processing—for new energy vehicle parts, heat sinks, and long profiles—two critical bottlenecks persist: material waste from tail scraps (traditional cutters leave 100+mm residuals) and low efficiency from repeated feeding (small-stroke machines require multiple loads). However, the JR-650CNC Auto Aluminum Cutter (a 6m stroke tail-free CNC machine) resolves these pain points: it integrates servo-driven automation, anti-deformation clamping, and one-time feeding to deliver 100% material utilization, ±0.1mm accuracy, and 2x faster production for long aluminum profiles.

1. What Is This 6m Stroke CNC Machine?

The JR-650CNC Auto Aluminum Cutter is a fully automated tool optimized for 6m-stroke cutting of long aluminum profiles (up to 230mm height, 420mm width). Unlike short-stroke alternatives, it supports one-time feeding of 6m profiles (no repeated loading), while its tail-free design eliminates residual waste—critical for high-cost large-profile production.

Furthermore, its core advantage lies in efficiency + material savings: servo motors drive automatic feeding/positioning/oiling, while the anti-injury clamping device secures thin-wall profiles (1–5mm thickness) without deformation. For instance, new energy vehicle part manufacturers using this cutter have cut material waste by 95% and boosted output by 120%.

2. Core Features of the JR-650CNC Auto Aluminum Cutter

This machine stands out for 3 large-profile-focused features, starting with servo-driven full automation.

In particular, high-torque servo motors automate every production step:

- Auto Feeding/Positioning: 6m maximum stroke supports one-time loading of long profiles;

- Auto Oiling/Sawing/Sorting: Reduces manual intervention to 0 (only profile loading is required);

- Stable Operation: Japanese-imported lead screws/guides ensure ±0.1mm cutting accuracy.

Beyond that, two design elements optimize large-profile quality:

- Tail-Free Cutting: Eliminates residual scraps (≤5mm waste vs. 100mm for traditional cutters);

- Anti-Injury Clamping Device: Even pressure distribution prevents warping in 1mm thin-wall long profiles.

A third key benefit is extended tool longevity and versatility:

- Cooling System: Lubricates saw blades during cutting, extending service life by 40%;

- Multi-Material Cutting: Processes aluminum, copper, PVC, and bakelite (ideal for mixed-component production).

3. Technical Specifications of This Tail-Free Cutter

Every parameter of the JR-650CNC Auto Aluminum Cutter is calibrated for 6m long-profile processing (paired with JR-455/550CNC for shorter profiles):

JR-650CNC Performance Characteristics & Tail-Free Cutting Advantages

JR-650CNC Technical Parameters & Material Compatibility

4. Application Scenarios for Large Aluminum Profiles

The JR-650CNC Auto Aluminum Cutter excels in 3 large-profile workflows, beginning with new energy vehicle long parts.

New energy vehicle chassis aluminum beams (6m length, 2mm thickness) require deformation-free, zero-waste cuts. Its anti-clamping device secures these parts, ensuring compliance with automotive safety standards (e.g., ISO 16750 for automotive components

Next, it is ideal for large heat sinks: industrial large heat sinks (6m length, dense fins) demand precise 90° cuts to maintain heat dissipation. This cutter’s cooling system delivers burr-free cuts, eliminating fin damage.

Finally, it suits long electrical enclosure profiles: PVC/steel electrical enclosure long profiles (6m length) require stable, efficient cutting. The 6m stroke machine processes 10+ profiles per hour, reducing production time by 50%.

5. Operation & Maintenance Guidelines

The JR-650CNC Auto Aluminum Cutter is designed for 2-hour operator training and 98% uptime, with a straightforward workflow:

-

- Power on (380V 50Hz) and set cutting parameters (length, quantity) via the touchscreen;

- Load a 6m profile into the auto-feeding tray;

- Press “Start” to initiate fully automated processing (feeding→clamping→oiling→sawing→sorting);

- Collect finished parts after the cycle ends.

To maintain performance, follow these scheduled steps:

- Daily: Clean saw blade debris and check cooling system oil level;

- Weekly: Lubricate lead screws/guides with imported industrial grease;

- Monthly: Calibrate cutting accuracy with a precision laser ruler (included);

- Quarterly: Replace saw blades if cut roughness exceeds Ra1.6.

6. Why Choose This 6m Stroke CNC Cutter?

For large-profile aluminum processors, the JR-650CNC Auto Aluminum Cutter delivers 3 strategic benefits:

- Zero Material Waste: Tail-free cutting saves 95% of residual profile costs;

- High Efficiency: One-time 6m feeding doubles production output;

- Precision Quality: ±0.1mm accuracy meets automotive/industrial large-part standards.

If you need a solution for shorter profiles (≤3m), explore our JR-550CNC Auto Aluminum Cutter —which offers similar precision for smaller-scale long profiles.

As demand for large, precision aluminum parts grows (especially in new energy sectors), this cutter is more than a machine—it’s a cost-saving, efficient tool for modern industrial large-profile production. Contact Jiurun Machinery today to request a custom quote or live demo of the JR-650CNC Auto Aluminum Cutter in action.

Thomas Klein –

“As the first user of the JR-650CNC in Germany, we’re thrilled with its 6-meter stroke capability! Cutting long aluminum profiles used to require 2-3 manual adjustments (and constant rework for errors)—now this machine handles full-length 6m pieces in one go, with 0.1mm-level precision. The CNC control keeps every cut consistent, and our daily output of long-profile parts has tripled. It’s the perfect solution for our large-scale aluminum fabrication projects!”