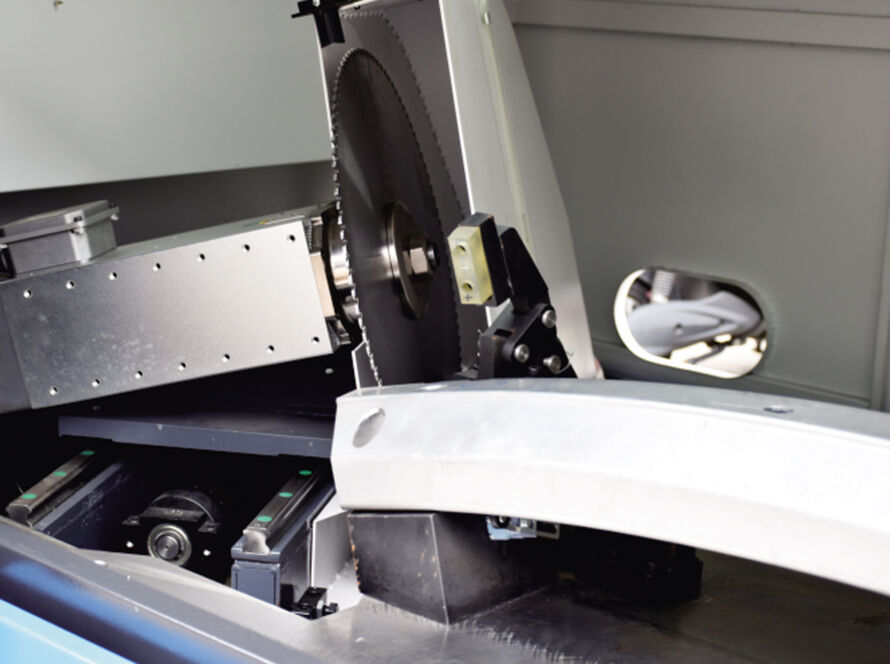

Jiurun aluminum profile cutting machine is designed for ultra-high precision aluminum profile processing.

As our flagship product line, every Jiurun aluminum cutting machine employs advanced servo systems and CNC technology. This enables micron-level precision in every cut, making it ideal for the aerospace, automotive, and electronics industries. For example, when cutting 7075-T6 aluminum alloy used in aircraft wings, our machines maintain a tolerance of ±0.01mm, ensuring seamless assembly with other precision parts. This high precision stems from collaborations with leading global companies: Japanese HIWIN linear guides effectively reduce vibration; German Siemens servo motors ensure stable high-speed operation without thermal deformation.

1. Efficiency-driven innovation

Jiurun Aluminum Cutting Machines also prioritize efficiency-driven innovation. Our automatic tool changer reduces downtime by 70% compared to manual tool changers, enabling uninterrupted production. Furthermore, real-time error compensation software automatically adjusts the cutting path during processing, effectively addressing material variations and increasing production efficiency by 30%. An automotive parts supplier achieved significant results after switching to our equipment: its daily output of aluminum door frames increased from 200 to 260 units, and its scrap rate decreased from 5% to 1.5%. Our R&D team is dedicated to optimizing workflows; every improvement aims to reduce waste and maximize production efficiency.

2. Use high-quality components to ensure reliability.

Reliability is at the heart of Jiurun Aluminum Cutting Machines. We collaborate with top global suppliers; in addition to HIWIN and Siemens, we source bearings from SKF in Sweden and pneumatic components from SMC in Japan. These components ensure a mean time between failures (MTBF) exceeding 10,000 hours, crucial for 24/7 production. A high-speed rail aluminum manufacturer operated our machines continuously for 18 months without any unplanned downtime. Our thermal stability design maintains consistent accuracy even during extended operation. Businesses can rely on our machines for stable operation, even in harsh industrial environments.

3. User-friendly intelligent operation

Jiurun aluminum cutting machines employ a user-centric intelligent operating system, simplifying complex operations. Through a human-machine interface (HMI), operators can set cutting parameters in just 2-3 minutes, requiring no specialized CNC programming skills. The system can also optimize the cutting path in real time, reducing material waste in customized aluminum profiles by up to 15%. Remote monitoring enables technicians to resolve 80% of problems remotely, shortening maintenance response time. For small and medium-sized enterprises, convenient operation means less employee training and more production time.

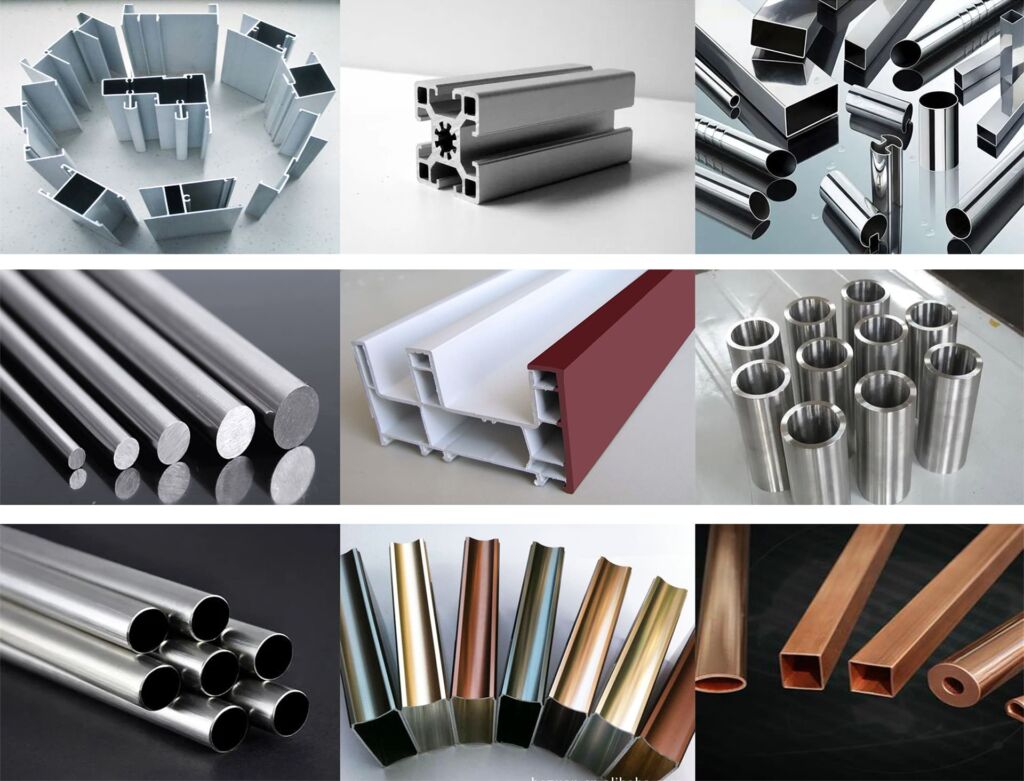

4. After-sales support and multi-functionality

Our commitment extends far beyond the machines themselves. Jiurun’s after-sales service network covers major hub cities such as Shanghai, Guangzhou, and Chongqing. We provide 48-hour on-site support for critical issues and offer lifetime technical guidance to ensure the equipment delivers maximum value for decades to come. Jiurun aluminum cutting machines are adaptable to a variety of applications. They can handle high-volume standard extrusions in the construction industry as well as cut custom aerospace parts with complex geometries. In the aerospace field, we have partnered with a leading manufacturer to develop a dedicated solution for titanium-aluminum alloy composites. This demonstrates our ability to innovate for specific needs. Whether in mass production or custom machining, our machines deliver consistently superior performance.