Description

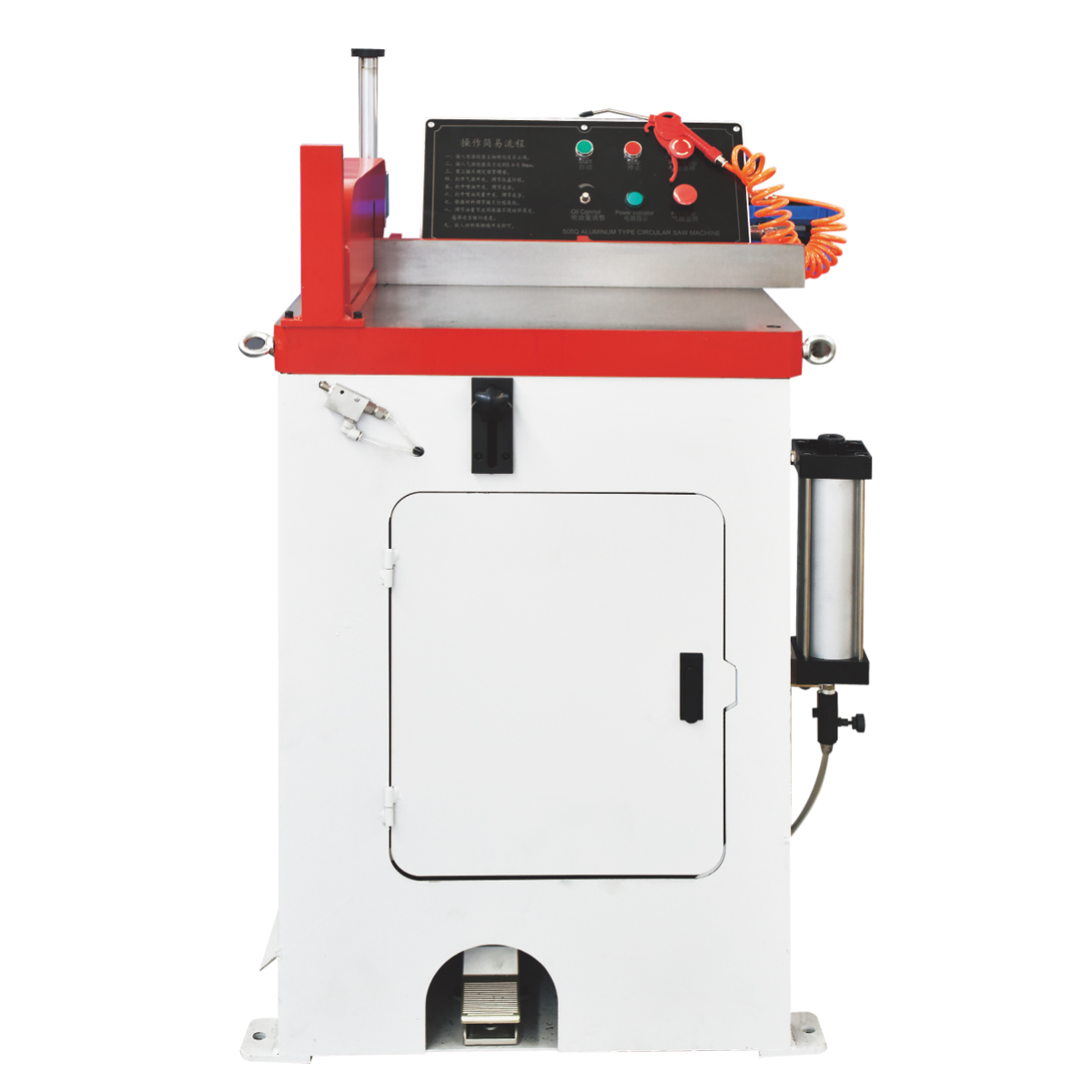

JR-455Q Semi-Auto Aluminum Cutter: Up-Down Clamp Cutting for Precision Aluminum Parts

In precision aluminum processing—especially for new energy vehicle parts, heat sinks, and copper components—two critical issues hinder quality: burrs on cut surfaces (wasting post-processing labor) and unstable clamping (causing profile deformation). The JR-455Q Semi-Auto Aluminum Cutter (an up-down clamp semi-automatic machine) resolves these: it integrates a hidden saw blade, automatic water spraying, and adjustable timing to deliver burr-free cuts, longer blade life, and stable clamping for diverse small-to-medium batch production.

1. What Is the JR-455Q Semi-Auto Aluminum Cutter?

The JR-455Q Semi-Auto Aluminum Cutter is a semi-automatic up-down clamp machine designed for 90°/45° cutting of aluminum/non-ferrous parts (up to 125mm height, 300mm width). Unlike basic semi-auto cutters, it balances operator control with automated precision: its up-down clamping system secures profiles evenly, while the hidden saw blade operates safely (no exposed rotating components) — critical for workshops processing delicate new energy vehicle parts.

Its core edge lies in precision + durability: automatic water spraying eliminates burrs (cut surface roughness ≤Ra1.6) and cools the blade, extending its service life by 40%. For new energy component manufacturers, this up-down clamp cutter reduces post-processing costs by 20%.

2. Core Features of This Up-Down Clamp Cutter

This up-down clamp cutter stands out for 3 precision-focused features:

2.1 Hidden Saw Blade for Safe Operation

The machine uses a hidden saw blade design: the blade operates within an enclosed chamber, moving up/down to cut clamped profiles—eliminating operator contact risks and aligning with industrial safety standards (ISO 12100). This is especially valuable for workshops with high staff turnover.

2.2 Automatic Water Spraying (Burr-Free + Longer Blade Life)

A built-in automatic water spraying system delivers two benefits:

- Burr-Free Cuts: Cools the blade during cutting to produce smooth, debris-free surfaces;

- Extended Blade Durability: Reduces blade wear, cutting replacement costs by 30% vs. dry-cutting alternatives.

2.3 Adjustable Clamping & Working Time

The machine lets users fine-tune two critical parameters:

- Clamping Timing: Adjusts pressure duration to avoid deformation in thin-wall profiles (1–3mm thickness);

- Working Time: Matches cutting speed to profile material (aluminum, copper, PVC) for consistent results.

3. Technical Specifications of the JR-455Q Semi-Auto Aluminum Cutter

Every parameter of the JR-455Q Semi-Auto Aluminum Cutter is calibrated for precision part processing (paired with JR-505Q/610Q for larger profiles):

4. Application Scenarios of This Precision Aluminum Cutter

This precision aluminum cutter excels in 3 high-demand workflows:

4.1 New Energy Vehicle Parts

New energy vehicle aluminum brackets (1–2mm thin-wall) require burr-free, deformation-free cuts. The machine’s up-down clamping secures these parts tightly, ensuring compliance with automotive component standards (ISO 16750).

4.3 Electrical Components

Copper/PVC electrical components require stable clamping to avoid conductivity issues. This semi-auto cutter’s adjustable timing ensures consistent pressure, reducing component reject rates by 10%.

5. Operation & Maintenance of the JR-455Q Semi-Auto Aluminum Cutter

The JR-455Q Semi-Auto Aluminum Cutter is designed for 1-hour operator training and 98% uptime:

5.1 Basic Operation Workflow

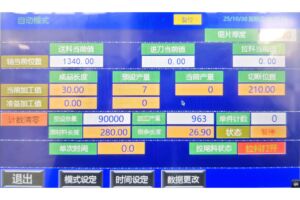

- Power on (380V 50Hz) and set air pressure to 5–8kg/cm²;

- Input cutting angle (90°/45°) and profile size via the control panel;

- Load the profile into the up-down clamp and press “Clamp”;

- Press “Cut” to initiate semi-automatic cutting (water spraying activates automatically).

5.2 Scheduled Maintenance

- Daily: Clean water spraying nozzles and check clamp pressure;

- Weekly: Lubricate up-down clamp rails with lithium-based grease;

- Monthly: Calibrate cutting angle with a precision protractor (included);

- Quarterly: Replace saw blades if cut roughness exceeds Ra1.6.

Jiurun Technology provides a 1-year full warranty and 24/7 remote technical support for this up-down clamp machine, minimizing downtime for precision production lines.

6. Why Choose the JR-455Q Semi-Auto Aluminum Cutter?

For precision aluminum processors, the JR-455Q Semi-Auto Aluminum Cutter delivers 3 strategic benefits:

- Burr-Free Precision: Automatic water spraying ensures ready-to-assemble parts;

- Stable Clamping: Up-down pressure avoids deformation in thin-wall profiles;

- Cost Efficiency: Longer blade life reduces replacement and labor costs.

Liam Walsh –

“As the first Australian user of the JR-455Q Semi-automatic Cutter, it’s perfect for our small workshop’s medium-batch aluminum jobs! Manual cutting used to take 20 minutes per 10-piece batch (with 2-3 mis-cuts every time)—now this semi-automatic machine cuts the same batch in 5 minutes, with zero errors. The half-auto setup lets us adjust quickly for different profile sizes, and even our part-time staff can operate it safely after 10 minutes of training. It’s the ideal balance of flexibility and efficiency for small-scale aluminum processing!”