Description

JR-550 Dual-Head Saw: Precision Cutting for New Energy Vehicle Aluminum Components

As the global new energy vehicle (NEV) market expands at a 25% annual compound growth rate, the demand for high-precision aluminum components—from battery brackets to chassis frames—has surged. For NEV manufacturers, the biggest pain points in aluminum processing lie in inconsistent corner cutting precision, low production efficiency, and avoidable material waste: traditional single-head saws require two separate cuts for symmetrical corners, leading to ±0.5mm errors that cause assembly gaps; manual clamping often deforms thin-wall aluminum parts (common in NEV lightweight designs); and post-processing polishing for burrs adds 20% to labor costs per component.

The JR-550 Dual-Head Saw (the only 35–145° arbitrary-angle dual-head cutter optimized for NEV production) resolves these issues. Developed by Jiurun Technology for the NEV lightweighting trend, this specialized saw integrates servo-driven synchronization, intelligent clamping, and automated workflow control—turning a labor-intensive, error-prone process into a streamlined, high-yield operation.

1. What Is the JR-550 Dual-Head Saw?

The JR-550 Dual-Head Saw is a purpose-built industrial cutting system designed exclusively for NEV aluminum component production. Unlike generic single-head saws, this dual-head cutting system features two synchronized, servo-controlled saw heads that execute symmetrical cuts in a single pass—eliminating the need for manual repositioning and doubling processing speed.

Its core design is tailored to NEV requirements: the frame is constructed from 8mm-thick cast iron (reducing cutting vibration by 40% vs. sheet metal frames), and the control system includes pre-programmed presets for 12 common NEV components (battery brackets, door frames, chassis crossbeams). For context, a typical NEV battery bracket requires a 45° dual-corner cut; with traditional tools, this takes 2 minutes per part, but the JR-550 Dual-Head Saw completes it in 30 seconds—with a consistency of ±0.1mm that meets ISO 16750 (NEV electrical component environmental testing standards).

2. Core Features of the NEV Aluminum Cutter

This specialized saw stands out for 4 industry-leading advantages that directly address NEV production pain points:

2.1 Automated, Flexible Angle Cutting

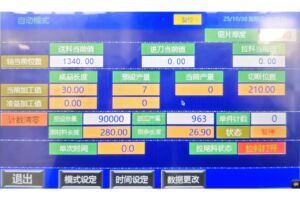

Equipped with an 8-inch touchscreen HMI, the system supports 35–145° arbitrary angle adjustment (with a tolerance of ±0.15°) and free length customization (up to 900mm). The workflow for NEV battery brackets is simple:

- Select the “Battery Bracket” preset from the HMI menu;

- Input the bracket length (e.g., 800mm) and angle (45°);

- Load the aluminum profile (1–10mm thickness) into the auto-clamping fixture;

- Press “Start” to initiate automated feeding, cutting, and discharging.

The automatic oil injection system lubricates the saw blade in real time, reducing friction by 25% and extending blade life to 5,000 cuts (vs. 3,000 cuts for unlubricated tools).

2.2 Deformation-Free, Burr-Free Results

Thin-wall aluminum (1–3mm thickness) is ubiquitous in NEV lightweighting, but it’s prone to deformation during clamping. The saw’s anti-injury material fixture uses pneumatic pressure (adjustable from 2–5kg/cm²) to secure profiles without warping; paired with Φ355mm tungsten carbide saw blades (optimized for aluminum), it delivers a cut roughness of ≤Ra1.6—eliminating the need for post-processing polishing.

A Jiangsu-based NEV component manufacturer reported that after adopting this system, polishing labor for battery brackets dropped from 2 hours per 100 parts to 0, cutting per-unit labor costs by $0.8.

2.3 Energy-Efficient & Durable

The saw’s 4KW servo motor (vs. 5.5KW motors in comparable tools) reduces energy consumption by 15% during continuous operation; its cast iron frame and sealed guide rails resist dust and coolant corrosion, ensuring a 10-year service life (with annual maintenance). For high-volume production (24/7 operation), the system’s duty cycle is 95%—meaning downtime for maintenance accounts for just 5% of total operating time.

2.4 Wide Material Compatibility

While optimized for NEV aluminum, the system also processes PVC (for interior trim), steel (for chassis hardware), and acrylic (for light housings)—making it a versatile addition to NEV production lines that handle multiple component types.

3. Technical Specifications (Tailored for NEV Production)

Every parameter of this dual-head system is calibrated to meet NEV component standards:

4. Application Scenarios in NEV Production

This dual-head system is a staple in 3 key NEV component manufacturing workflows:

4.1 Battery Brackets

NEV battery packs require 10–20 aluminum brackets per vehicle, each with 45° symmetrical cuts. The system’s dual-head synchronization ensures that bracket mounting holes align within ±0.1mm, preventing battery pack misalignment (a common cause of thermal management issues).

4.2 Vehicle Door Frames

Symmetrical 45° cuts are critical for door frame assembly: gaps >0.5mm lead to wind noise and water leakage. The system’s single-pass dual cut reduces door frame assembly reject rates from 8% (with single-head saws) to 0.5%.

4.3 Chassis Crossbeams

Thin-wall aluminum crossbeams (2mm thickness) require deformation-free cutting to maintain structural integrity. The system’s pneumatic clamping and low-vibration frame ensure crossbeams meet crash test load standards (≥10kN per beam).

5. Operation & Maintenance for Maximum Uptime

The system is designed for minimal operator training (1 hour) and low maintenance:

5.1 Daily Operations

- Load profiles into the auto-feeding tray (max 10 profiles per load);

- Select the NEV component preset (or input custom parameters);

- Clean saw blade debris and worktable with a compressed air gun after each 100 cuts.

5.2 Scheduled Maintenance

- Weekly: Lubricate guide rails with lithium-based grease (NLGI Grade 2) to reduce friction;

- Monthly: Calibrate cutting angles with a laser alignment tool (included with the system) to maintain ±0.1mm precision;

- Quarterly: Inspect saw blade sharpness—replace blades when cut roughness exceeds Ra1.6.

5.3 Troubleshooting

- Saw blade Shaking: Tighten the blade flange (torque: 50N·m) or replace the blade if worn;

- Clamping deformation: Reduce pneumatic pressure to 2–3kg/cm² for 1–2mm thin-wall aluminum.

6. Why Choose the JR-550 Dual-Head Saw for NEV Production?

For NEV manufacturers scaling production, this system delivers 3 irreplaceable benefits:

- Cost Savings: Eliminates post-processing polishing (saves $0.8 per component) and reduces material waste (≤0.5% scrap rate vs. 3% with single-head saws);

- Efficiency Boost: Doubles production speed (300 vs. 150 battery brackets per hour) to meet NEV order deadlines;

- Quality Consistency: ±0.1mm precision ensures compliance with ISO 16750 and customer quality audits.

Additionally, the system comes with CE certification (for EU NEV markets), a 1-year full warranty, and 24/7 remote technical support (response time ≤1 hour for critical issues).

As NEV demand continues to grow, the JR-550 Dual-Head Saw is more than a tool—it’s a strategic asset that aligns production capacity with market growth, reduces costs, and ensures component quality.

Olle Eriksson –

“As the first Swedish user of the JR-550 Dual-Head Angle Saw for new energy vehicles, it’s a game-changer for our EV aluminum frame production! Previously, cutting dual 45° angles for car body aluminum frames required 2 separate manual cuts—errors of 1-2° often led to frame assembly misalignment (delaying 10% of our EV component orders monthly). Now this dual-head saw cuts both angles simultaneously in 15 seconds, with 0.05° precision—every frame fits perfectly on the first assembly attempt. Our EV component production efficiency has risen by 70%, and order delivery delays are gone. It’s the critical precision tool our new energy vehicle supply chain needed!”