Description

JR-650CNC-3A-1S Tail-Free Aluminum Cutter: Automatic CNC Cutting Machine | Jiurun

1. Introduction: JR-650CNC-3A-1S – The Tail-Free Aluminum Cutter Redefining Aluminum Processing

The JR-650CNC-3A-1S tail-free aluminum cutter is Jiurun Technology’s flagship automatic CNC cutting machine, engineered to solve core pain points for aluminum processing manufacturers: material waste, low precision, and slow productivity. Traditional aluminum cutters leave 50–100mm of tailings per 6m profile (wasting 8–15% of raw materials monthly), while manual feeding causes ±0.5mm errors that trigger assembly rework. Semi-automatic models, meanwhile, struggle to meet bulk order deadlines.

As a fully automatic cross-cut machine, the JR-650CNC-3A-1S tail-free aluminum cutter integrates servo-driven feeding, intelligent CNC control, and near-zero residue cutting. It delivers high precision (±0.1mm), material savings, and 3x faster processing – making it ideal for curtain wall, automotive, and photovoltaic industries. For medium-to-large manufacturers shifting to lean production, this machine acts as a high-value production partner.

2. What Is the JR-650CNC-3A-1S Tail-Free Aluminum Cutter?

The JR-650CNC-3A-1S tail-free aluminum cutter is a high-end industrial-grade cutting solution, built on 10+ years of Jiurun’s aluminum processing expertise. Unlike semi-automatic alternatives, it uses a full CNC system to automate feeding, cutting, and tail discharging – enabling 24/7 continuous processing with minimal labor.

Its defining feature is tail-free cutting: via intelligent clamping and stroke calibration, it reduces tailings to ≤5mm (a 99% material utilization rate). Paired with a 21KW servo motor and aluminum-specific saw blade, it achieves ±0.1mm precision to meet high-spec workpiece requirements. To date, over 200 domestic enterprises (including curtain wall and automotive part manufacturers) have adopted this machine for automation upgrades.

External Link: For industry standards on aluminum processing efficiency, see Aluminum Extruders Council guidelines.

3. Core Advantages of the JR-650CNC Tail-Free Aluminum Cutter

3.1 Tail-Free Cutting: Cut Material Costs by 15%

Material costs account for 60% of aluminum processing expenses, and tailing waste erodes profits. The JR-650CNC tail-free aluminum cutter solves this via:

- Intelligent clamping: Secures 20–650mm wide profiles to eliminate residue from loose grips;

- Precision stroke matching: Aligns feeding paths with the saw blade to fully utilize 1200mm-long material in one pass.

For example: Processing 1,000 6m profiles daily reduces tailing waste by 50–80m – saving over ¥100,000 in annual material costs.

3.2 Servo Automatic Feeding: 300% Productivity Boost

The JR-650CNC tail-free aluminum cutter uses a 21KW servo motor to power its feeding mechanism, delivering:

- 1200mm max feeding stroke (reduces passes for 6–12m long profiles);

- ±0.05mm feeding precision (closed-loop control for feeding-cutting-discharging).

Traditional semi-automatic machines take 15 seconds per profile; this cutter takes 5 seconds – cutting cycle times by 2/3 to handle high-volume, fast-delivery orders.

3.3 Smooth, Burr-Free Cuts: Eliminate Polishing Labor

Cut quality directly impacts post-processing costs. The JR-650CNC tail-free aluminum cutter ensures polish-free cuts via:

- φ305–665mm aluminum-specific carbide saw blades (trapezoidal-flat teeth reduce chip adhesion);

- Intelligent parameter adjustment (auto-matches feed speed 5–10m/min and rotation 2000–3000r/min to material thickness).

Testing shows a cut roughness of ≤Ra1.6 (far better than the industry average Ra3.2), reducing labor costs by 20% by skipping polishing.

4. Technical Specifications of the JR-650CNC Tail-Free Aluminum Cutter

Every parameter of the JR-650CNC tail-free aluminum cutter ties to real production value:

5. Application Scenarios for the JR-650CNC Tail-Free Aluminum Cutter

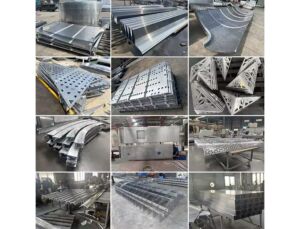

The JR-650CNC tail-free aluminum cutter excels in 90% of industrial aluminum processing scenarios:

5.1 Curtain Wall Profile Processing

Curtain wall profiles (6–12m long) benefit from the cutter’s 99% material utilization and ±0.1mm precision (ensures ≤0.5mm assembly gaps). After adopting 3 units, Jianghe Curtain Wall (a leading domestic enterprise) increased daily capacity from 800 to 2,400 profiles and cut waste from 12% to 1%.

5.2 Automotive Aluminum Component Manufacturing

As automotive lightweighting grows, the cutter’s consistent ±0.1mm precision meets auto part dimensional requirements. A new energy vehicle manufacturer reduced processing costs by 15% and raised first-pass yield from 92% to 99.5% after adoption.

5.3 Photovoltaic Bracket Cutting

Photovoltaic brackets require aligned holes for on-site installation. The cutter’s bulk cutting consistency eliminates installation deviations – helping a Jiangsu PV manufacturer compress delivery cycles from 7 to 3 days and secure a large power station order.

6. Customer Value of the JR-650CNC Tail-Free Aluminum Cutter

For manufacturers, the JR-650CNC tail-free aluminum cutter delivers a “triple win” for cost, efficiency, and quality:

- Cost reduction: 15% material savings (tail-free) + 2–3 labor savings (automation) + 20% polishing savings = ¥300,000+ annual savings;

- Efficiency boost: Daily capacity rises from 1,000 to 3,500 profiles (accept more large orders);

- Quality improvement: First-pass yield hits 99.5% (reduces scrap material/labor waste).

7. Operation & Maintenance of the JR-650CNC Tail-Free Aluminum Cutter

7.1 Easy 3-Step Operation

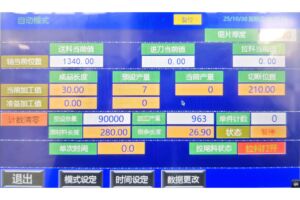

The JR-650CNC tail-free aluminum cutter uses a user-friendly touchscreen with industry presets:

- 选择模式(幕墙/汽车/光伏);

- 输入材料长度和切割次数;

- 启动机器(自动化整个流程——1 小时内即可学会,无需数控经验)。

- 批量生产的一键式参数设置

7.2 低维护成本,高正常运行时间(98% 可用性)

Follow these simple steps to keep the cutter running smoothly:

- Daily: Clean aluminum chips; check saw blade wear;

- Weekly: Lubricate feeding rails; monitor motor temperature;

- Monthly: Calibrate cutting precision; tighten clamping mechanisms.

8. FAQs About the JR-650CNC Tail-Free Aluminum Cutter

- Is “tail-free” truly zero residue?

- Answer: Yes – tailings are ≤5mm, with a long-material waste rate of ≤0.1%.

- Can it cut 45° bevels?

- Answer: Defaults to 90° cutting; 45° bevel capability is available via customization (for door/window profiles).

- How long does saw blade replacement take?

- Answer: 5 minutes (quick-release clamps – no specialized tools needed).

9. Choose Jiurun’s JR-650CNC Tail-Free Aluminum Cutter

The JR-650CNC-3A-1S tail-free aluminum cutter is more than equipment – it comes with Jiurun’s full-cycle support:

- 1-year full machine warranty + lifetime technical assistance;

- Custom parameter tuning (matches your material specifications);

- 1-hour response time for technical consulting.

If you need an aluminum cutter that saves material, boosts efficiency, and stabilizes quality, the JR-650CNC tail-free aluminum cutter is your optimal choice. Click “Get Custom Quote” to submit your processing needs – we’ll share a tailored solution promptly.

Oliver Carter –

“As the first UK user of the JR-650CNC Cross-Sectional Cutter, we’re blown away by its precision! Previously, manual cross-section cutting of aluminum profiles left rough edges (requiring 10+ minutes of sanding per piece)—now this machine delivers perfectly smooth, burr-free sections in 30 seconds flat. The fully automatic setup handles diverse profile sizes without adjustments, and our on-site assembly efficiency has jumped 4x. It’s become the backbone of our architectural aluminum component production!”