Automatic Feeding System: Precision-Driven Automation for Aluminum Production

1. Precision Automation for Aluminum Production

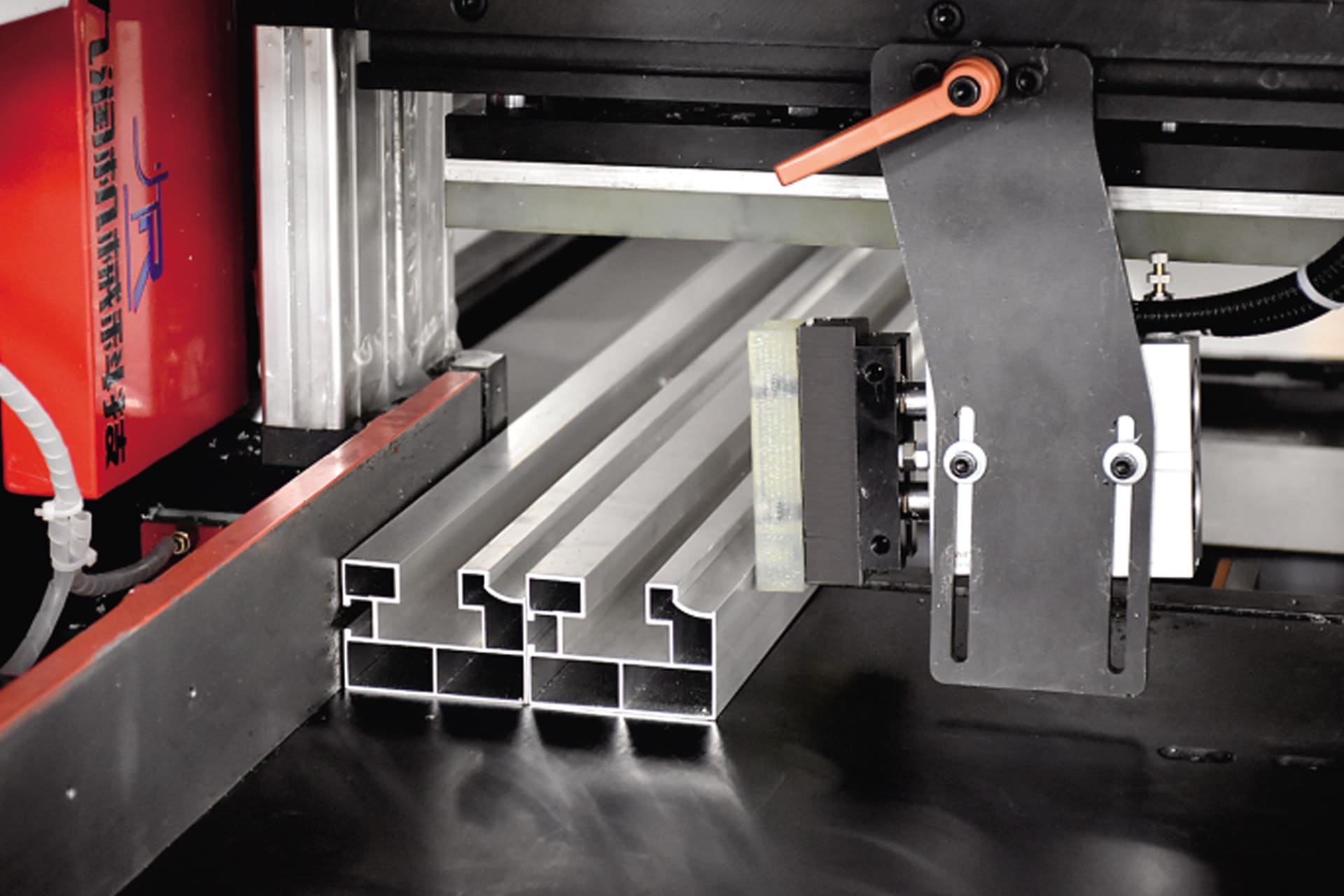

Jiurun’s automatic aluminum feeding system is an advanced automation solution designed for manufacturers requiring precision, consistency, and long-term reliability. Utilizing high-performance servo motors, the system achieves a feeding accuracy of ±0.1 mm, ensuring seamless aluminum profile handling for continuous operations. Every movement is precisely controlled, allowing the feeding process to synchronize perfectly with the cutting head and saw blade, which minimizes vibration and guarantees burr-free, smooth results.

This system is especially suited for high-volume aluminum extrusion, solar frame, and architectural window production lines, where speed and stability are critical. By reducing manual intervention, Jiurun helps factories achieve efficient production cycles and higher output with fewer errors.

2. Advanced Control and Intelligent Operation

At the heart of the Jiurun automatic aluminum feeding system lies an intelligent CNC control interface. Operators can easily set feeding length, cutting speed, and batch quantity through the touch-screen panel, allowing flexible production scheduling. The control software includes smart diagnostics, fault alerts, and an automatic counting feature that records each processed piece with accuracy.

This intelligent feedback mechanism not only reduces downtime but also supports data tracking and preventive maintenance. The machine automatically stops when abnormalities occur, protecting both the operator and the machine. These functions make Jiurun’s feeding system ideal for 24/7 production environments requiring precision and reliability.

3. Efficiency and Productivity Advantages

Unlike conventional manual systems, the Jiurun automatic aluminum feeding system provides non-stop material delivery. With servo synchronization, it ensures each aluminum profile is positioned correctly before cutting begins, eliminating wasted time and improving yield. The automatic feeding system can achieve up to 120 cycles per hour, allowing manufacturers to increase productivity by 30–40% compared to manual or semi-automatic solutions.

Furthermore, its low energy consumption design and optimized servo drive help reduce power use, contributing to cost savings and environmental protection. The system’s modular structure allows easy integration with existing CNC cutting machines, creating a flexible, scalable solution for modern factories.

4. Customization for Diverse Applications

Recognizing that every production line has unique requirements, Jiurun provides tailor-made solutions for its automatic aluminum feeding system. Users can customize feeding lengths, clamp types, conveyor dimensions, and integration levels depending on their product type—whether it’s large aluminum extrusions, narrow window frames, or precision-cut tubes.

Jiurun’s engineering team collaborates closely with customers to ensure smooth integration into both new and existing production setups. This flexibility makes it an ideal solution for manufacturers across Southeast Asia and the Middle East who demand durable, easy-to-maintain, and efficient machinery.

5. Reliability, Durability, and Safety

The system structure uses a high-strength welded frame and precision linear guides, providing long-term operational stability even under high-speed continuous workloads. Each component is rigorously tested to meet international standards for industrial safety and endurance.

Automatic clamping, anti-slip rollers, and safety sensors protect the operator during operation. Emergency stop switches and alarm systems are built into every model. With minimal maintenance needs and an extended service life, Jiurun’s feeding system ensures a low total cost of ownership and dependable long-term performance.

6. Integrated Industrial Connectivity

The Jiurun automatic aluminum feeding system supports digital connectivity and data monitoring. It can be linked with MES or ERP systems to share real-time production data and automatically generate reports on throughput and material usage.

This integration helps factory managers monitor performance indicators such as efficiency, downtime, and material utilization rates remotely. By bringing digital control to aluminum manufacturing, Jiurun enables smart, data-driven production that supports Industry 4.0 transformation.

7. Commitment to Quality and Global Service

Every Jiurun feeding system undergoes strict inspection before shipment. Our global service team provides technical support, training, and installation guidance to help clients achieve optimal performance from day one. With customers across Southeast Asia, the Middle East, and Europe, Jiurun has earned a reputation for delivering reliable automatic aluminum cutting and feeding systems that meet international quality standards.

Our mission is to empower manufacturers with intelligent equipment that enhances efficiency, ensures precision, and drives sustainable growth in aluminum processing industries.