CNC Intelligent Control System: Precision & Automation with German PA Tech

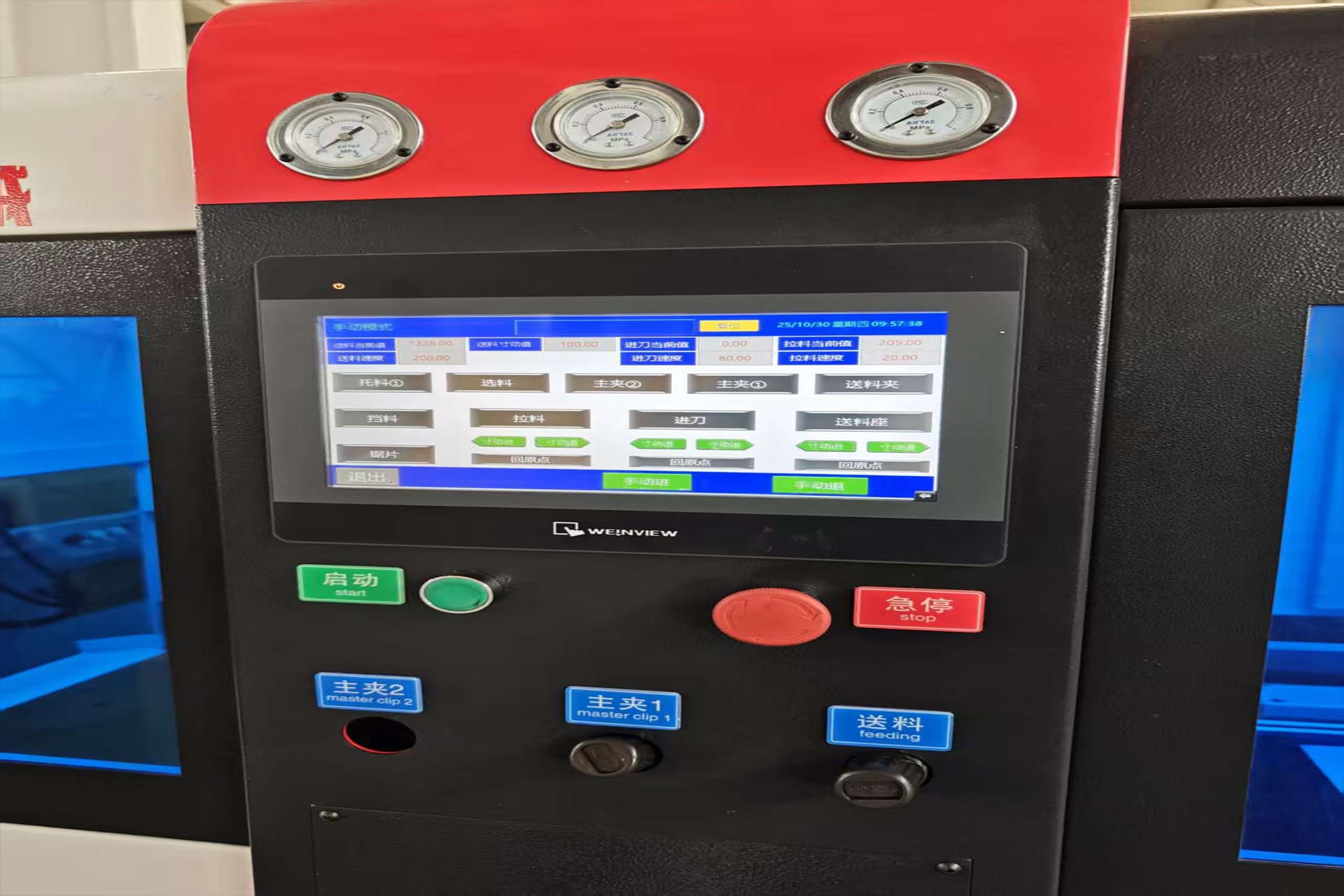

Jiurun Machinery’s CNC Intelligent Control System leverages German PA technology to redefine precision and automation in aluminum cutting. Featuring automatic counting, real-time precision monitoring, and intelligent fault detection, this system ensures seamless, error-free operation—critical for high-volume, high-accuracy production in industries like automotive, aerospace, and construction.

1. German PA Technology: Core of Precision Control

At the heart of the CNC Intelligent Control System is German PA control technology. This industry-leading tech provides ultra-responsive command execution, ensuring every cutting action—from speed adjustment to blade positioning—happens with millisecond precision. For example, when cutting aerospace-grade aluminum alloys, the system maintains ±0.05mm tolerance, meeting strict aerospace manufacturing standards.

2. Automatic Counting: Streamline Production Tracking

The system’s automatic counting feature eliminates manual tallying of cut aluminum profiles. As each piece is processed, the CNC system logs and displays the count in real time—simplifying inventory management and production reporting. A Turkish automotive parts factory reduced administrative time by 20% using this automated counting, as workers no longer spent hours manually counting cut aluminum components.

3. Precision Monitoring: Real-Time Performance Insights

Real-time precision monitoring keeps operators informed of every detail: cutting speed, blade wear, material alignment, and more. If deviations from set parameters occur (e.g., a slight misalignment), the system alerts operators instantly. This proactive monitoring prevents defective cuts and reduces material waste—an Indian aluminum window manufacturer saw scrap rates drop by 15% after adopting the system’s precision oversight.

4. Intelligent Fault Detection: Minimize Downtime

Intelligent fault detection identifies potential issues before they cause breakdowns. The system analyzes operational data (vibration, temperature, motor load) to spot anomalies, then triggers alerts or automatic corrections. A Brazilian industrial plant cut unplanned downtime by 35% with this feature, as the CNC system predicted and addressed a motor issue before it halted production.

5. Seamless Integration with Aluminum Cutting Workflows

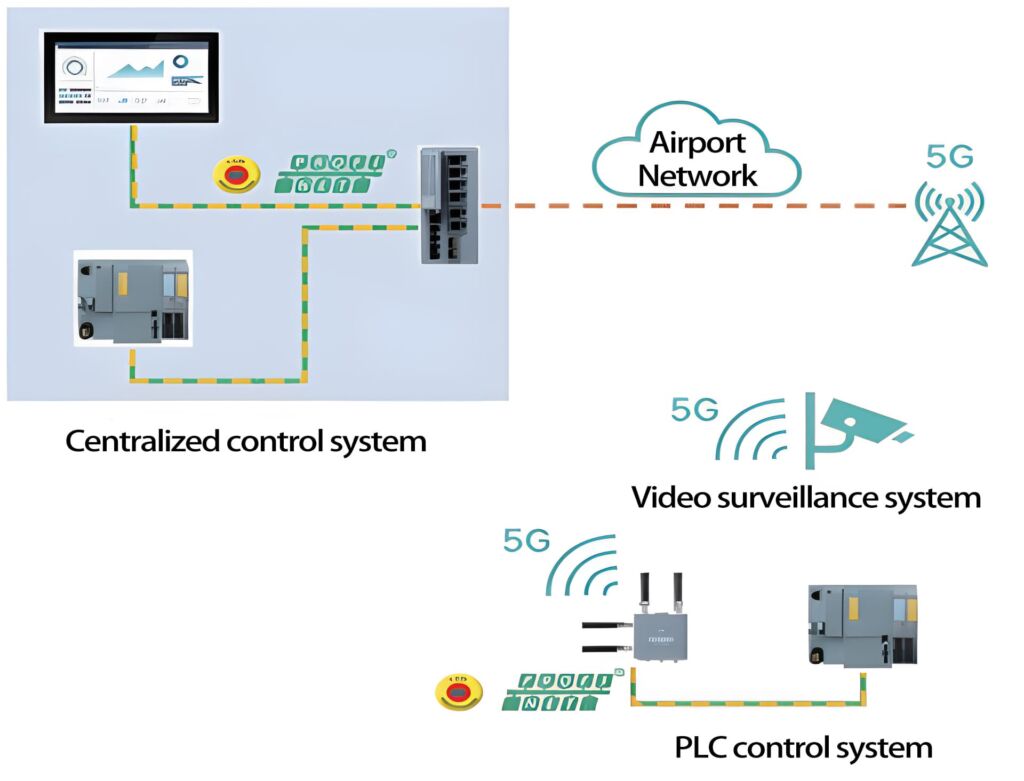

The CNC Intelligent Control System integrates smoothly with Jiurun’s automatic feeding, cutting, and finishing systems—creating a unified, automated workflow. Whether connected to a high-efficiency cutter or a heavy-duty aluminum feeder, the CNC system synchronizes all components for consistent, end-to-end precision. This integration is key for factories aiming to scale production without compromising quality.