Customized Automation Solutions for Aluminum Cutting: Precision-Tailored Efficiency

Jiurun Machinery’s Customized Automation Solutions for Aluminum Cutting redefine efficiency in aluminum processing. They tailor every aspect of the production process—from cutting length and feeding speed to the entire automation workflow. Our solutions adapt precisely to your aluminum production line’s unique needs. This ensures seamless integration, reduced material waste, and maximum productivity. Such customization is vital. It serves industries like construction, automotive, and aerospace. In these sectors, aluminum components demand both precision and scalability.

1. Tailor-Made Cutting Length: Align with Exact Production Demands

Every aluminum manufacturing scenario has distinct length requirements. These range from window frames and automotive parts to industrial extrusions. Our Customized Automation Solutions for Aluminum Cutting let you configure cutting lengths precisely—down to ±0.1mm. This eliminates material waste. It also ensures each piece fits perfectly into downstream processes. For example, a Saudi Arabian aluminum factory cut scrap rates by 18%. They did this after using our system for solar panel frames. The customized length settings matched their exact design specs. There was no overcutting or undercutting.

2. Optimized Feeding Speed: Balance Throughput and Precision

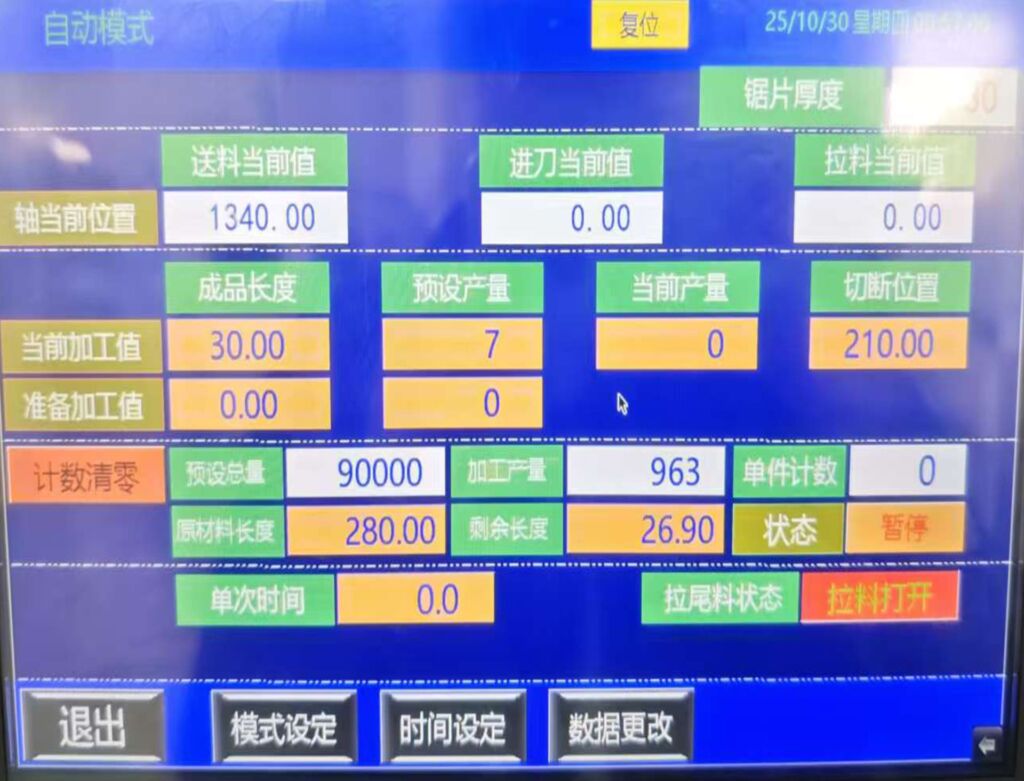

Feeding speed directly impacts production volume and cutting accuracy. With Aluminum Cutting Custom Automation, we fine-tune feeding speed. We match it to your material type (like thin aluminum sheets or thick extrusions). We also align it with your desired output. For instance, when processing delicate aerospace aluminum sheets, the system slows feeding. This maintains ±0.05mm precision. For mass-produced construction profiles, it speeds up to 120pcs/h. Even then, it still holds ±0.1mm tolerance. This balance lets you maximize throughput without sacrificing quality.

3. Streamlined Automation Workflow: End-to-End Integration

Our Customized Automation Solutions for Aluminum Cutting don’t just optimize individual steps. They integrate seamlessly into your entire production line. This includes syncing with upstream systems (like automated conveyors). It also connects with downstream processes such as anodizing or assembly. In an Indonesian aluminum door factory, our workflow integration cut changeover time by 40%. The system auto-adjusted cutting parameters, feeding speed, and length settings. This happened when switching from standard doors to custom-sized frames. As a result, overall equipment efficiency (OEE) rose by 25%.

4. Adaptable to Diverse Aluminum Production Scales

Whether you operate a small workshop or a large factory, our solutions scale. Small workshops might make bespoke architectural profiles. Large facilities could mass-produce aluminum for infrastructure. Customized Automation Solutions for Aluminum Cutting fit both scenarios. We design systems for low-volume, high-mix production (with quick custom spec changeovers). We also create setups for high-volume, standardized runs (enabling 24/7 operation). This adaptability benefits all businesses. Startups cut labor costs. Enterprises speed up time-to-market.

5. Global Expertise in Custom Aluminum Automation

Jiurun’s Customized Automation Solutions for Aluminum Cutting are trusted in over 30 countries—including Malaysia, UAE, and Vietnam. Our team combines global engineering expertise with local market insights. We audit your production line on-site. We analyze factors like floor space, existing machinery, and labor workflows. Then, we design and implement tailor-made aluminum cutting system upgrades. These deliver measurable ROI. A Malaysian client saw a 30% boost in production capacity. They also cut operating costs by 22% within six months of adoption.