Heavy-Duty Aluminum Cutter: Industrial Precision for 2600mm Profiles

Jiurun Machinery’s Heavy-Duty Aluminum Cutter delivers industrial-grade precision for cutting aluminum profiles up to 2600mm. Equipped with a dual-clamping stability system, this cutter ensures secure, vibration-free processing—critical for large-scale projects in construction, transportation, and heavy industry.

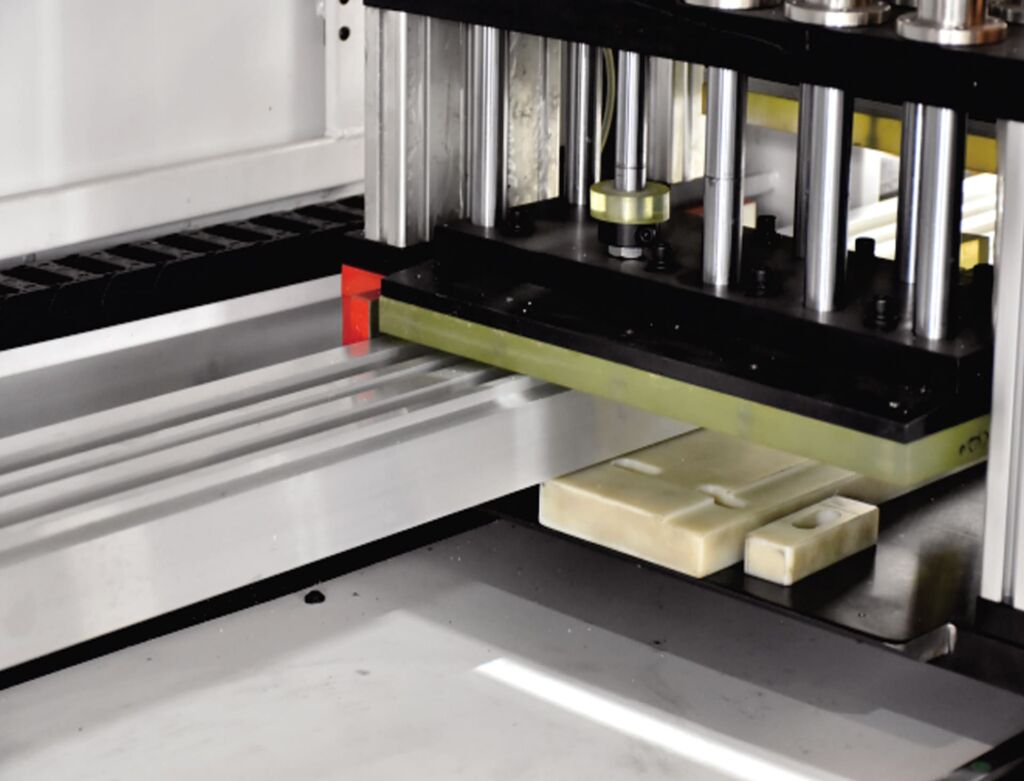

1. Dual-Clamping Stability: Secure Long Profiles

The cutter’s dual-clamping stability system grips aluminum profiles from two sides, eliminating movement during cutting. This design is essential for processing extra-long profiles (up to 2600mm) without warping or misalignment. For example, a construction firm in Dubai used this cutter to produce 2.5-meter aluminum curtain wall sections, achieving perfect straight cuts with no post-processing needed.

2. 2600mm Cutting Capacity: Meet Large-Scale Needs

With a maximum cutting length of 2600mm, the Heavy-Duty Aluminum Cutter addresses demands for oversized aluminum components. Industries like aerospace (for wing spars) and infrastructure (for bridge extrusions) rely on this capacity to avoid joining multiple smaller pieces. A German aerospace supplier reduced assembly time by 30% by cutting full-length aluminum spars in one pass.

3. Industrial-Grade Durability: For Continuous Operation

Built with high-strength steel and reinforced components, the cutter withstands 24/7 operation in industrial settings. Its robust build reduces downtime from wear and tear, making it ideal for factories with high-volume production. A Chinese aluminum factory reported a 40% increase in monthly output after switching to this cutter for non-stop shifts.

4. Precision Cutting: Tight Tolerances for Assembly

Even with heavy-duty use, the cutter maintains ±0.1mm tolerance—ensuring aluminum parts fit seamlessly in downstream assembly. This precision is vital for applications like automotive frames or modular building systems, where misaligned cuts cause costly delays. A Turkish automotive supplier cut rework rates by 25% thanks to the cutter’s consistent accuracy.

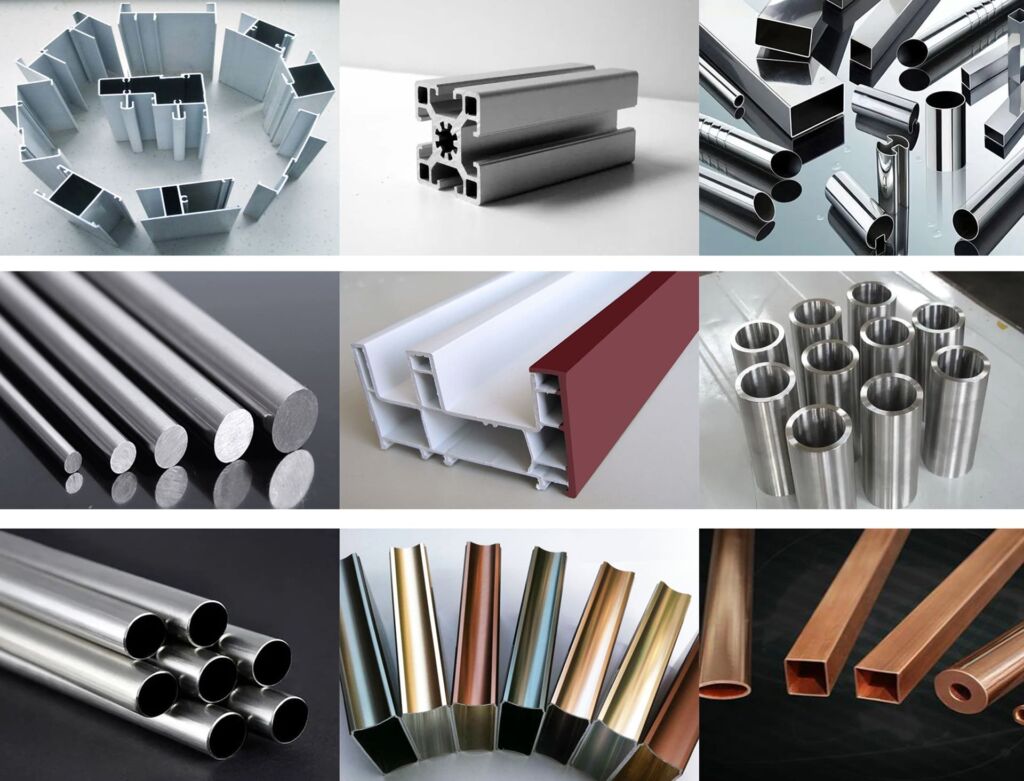

5. Versatile for Diverse Aluminum Applications

The Heavy-Duty Aluminum Cutter isn’t limited to standard profiles—it handles varied shapes (angles, tubes, sheets) and alloys (including high-strength aerospace grades). Operators adjust cutting speed and blade depth based on material specs, making it versatile for custom projects. From energy sector heat sinks to architectural facades, it adapts to diverse industrial needs.